Basic Info.

Model NO.

Factory standard

Size

Made as Per Customers′ Requests

Customized

Customized

Type

Cutting

Material

Cemented Carbide

Certification

ISO 9001:2008, ISO 9001:2000, GS, CE

Product Name

Tungsten Carbide Cutting Tool

Chemical Composition

Co, W, Customized

Surface Quality

Ground, Polished, Coated

Grade

Zk30UF, Yg8

Delivery

About 25-30 Days

OEM

Available

Transport Package

Customer Standard, Neutral Packing Available

Specification

ISO 9001

Trademark

FOTMA

Origin

China

HS Code

82077000

Production Capacity

50000 PCS/Year

Packaging & Delivery

Package Size

14.00cm * 14.00cm * 25.00cm

Package Gross Weight

10.000kg

Product Description

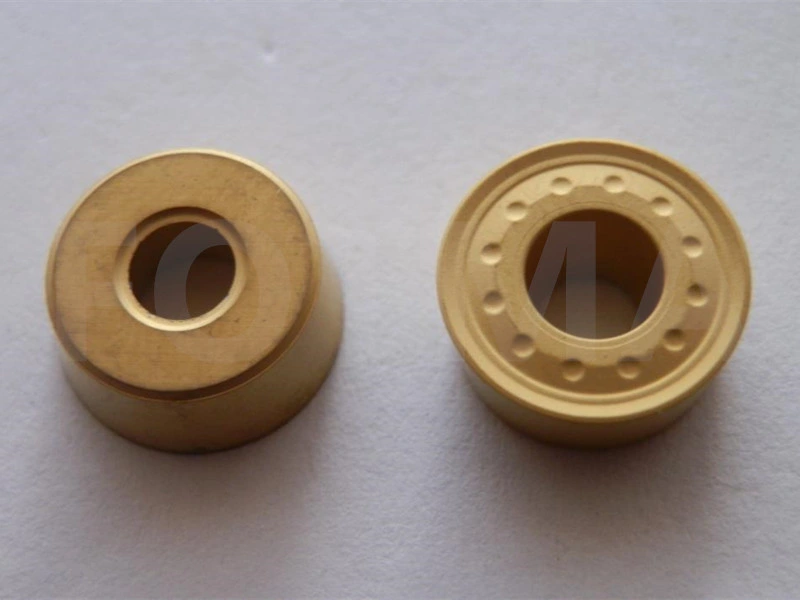

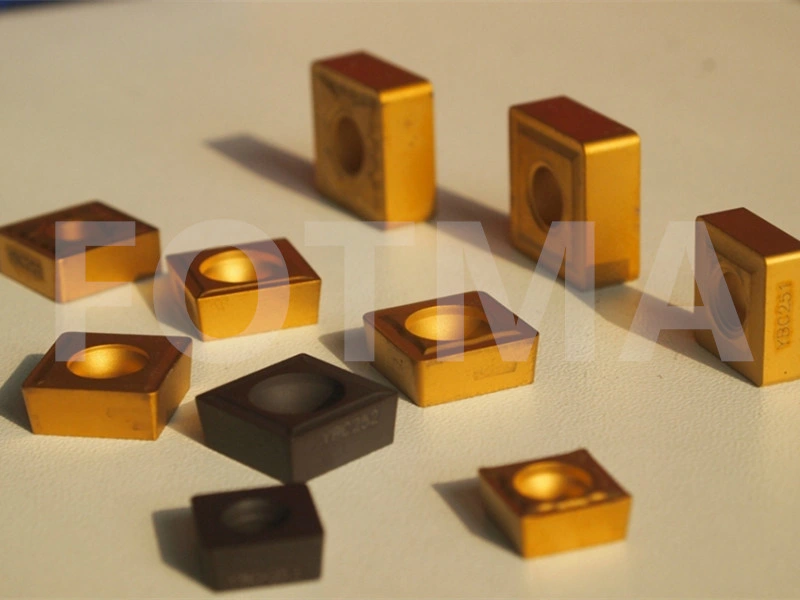

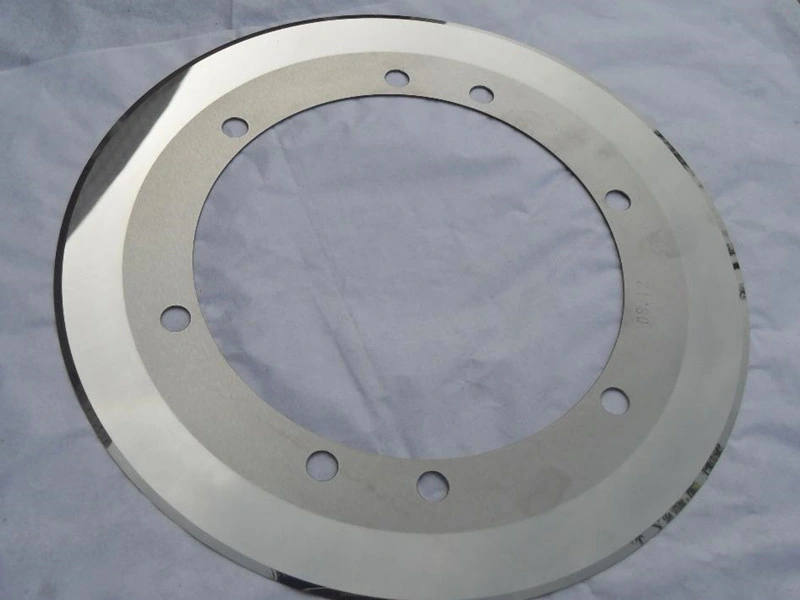

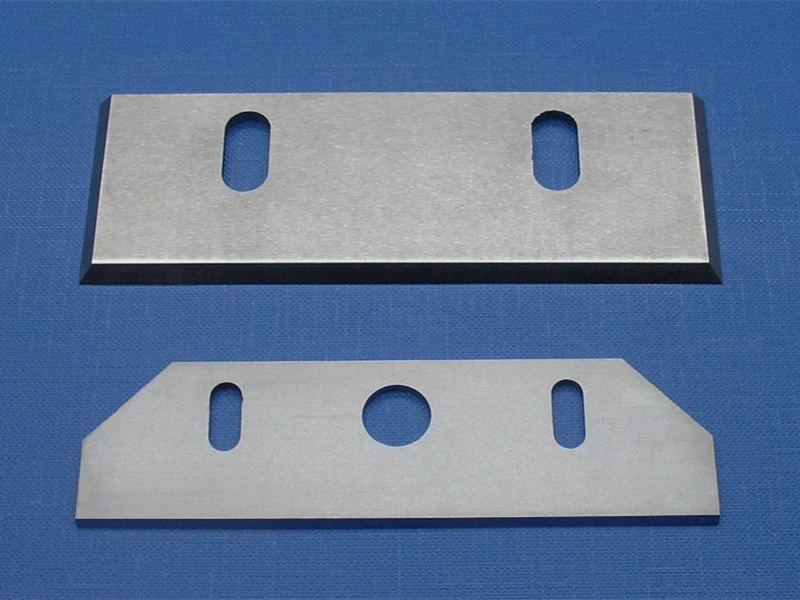

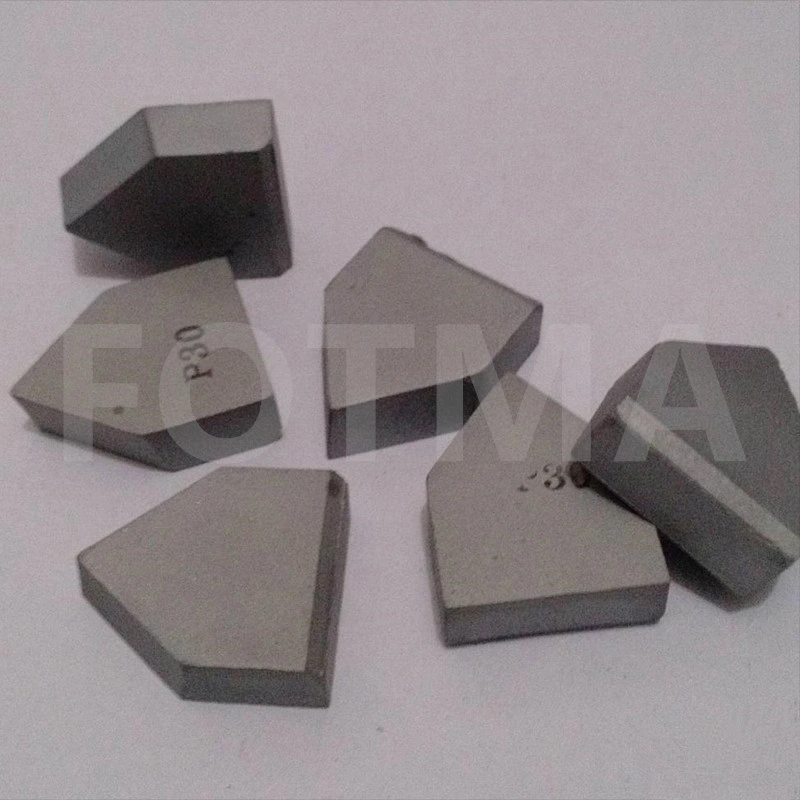

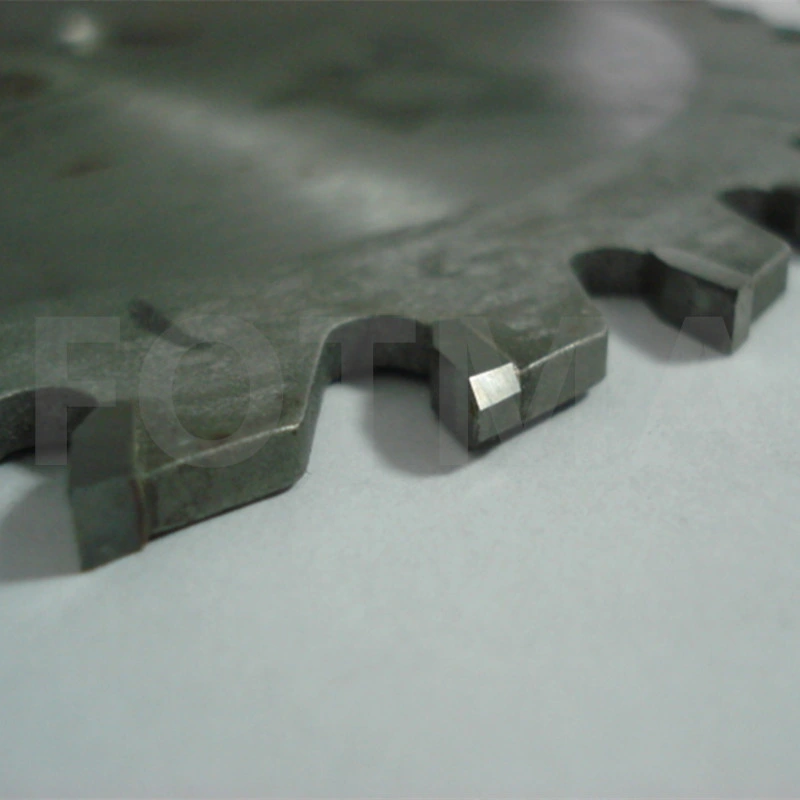

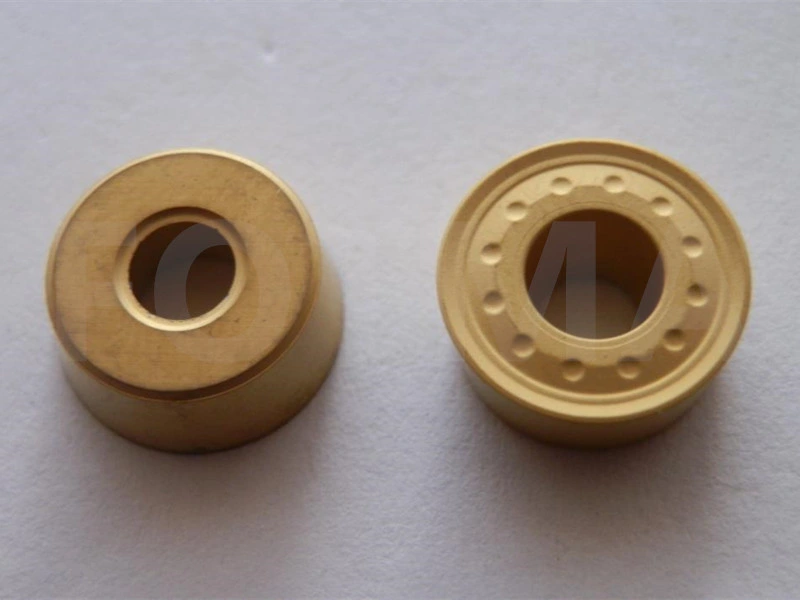

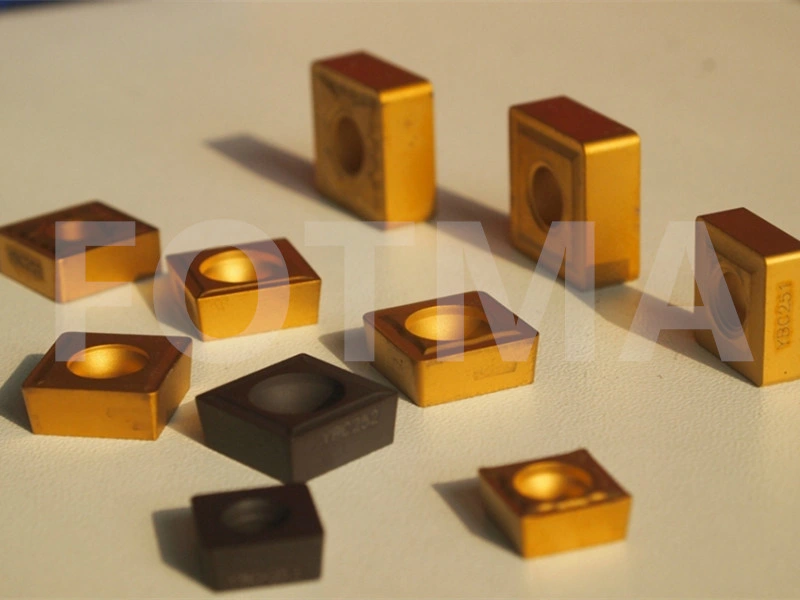

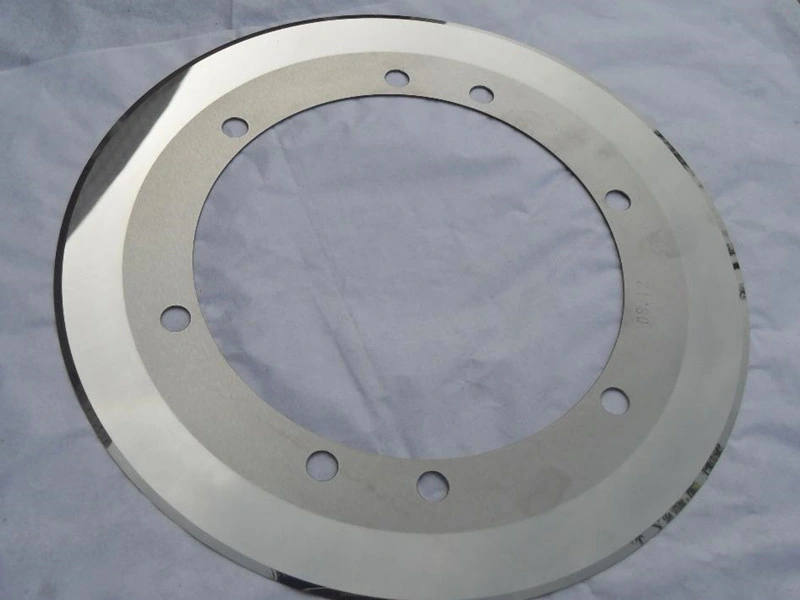

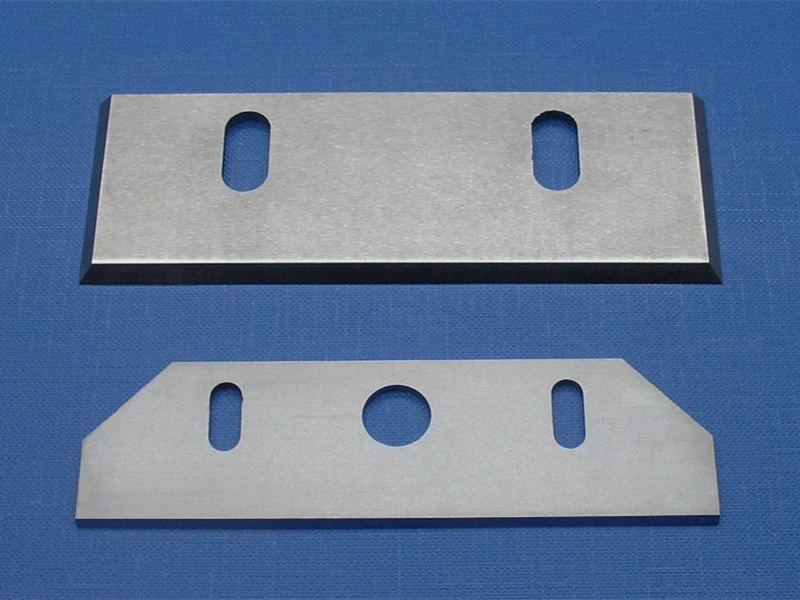

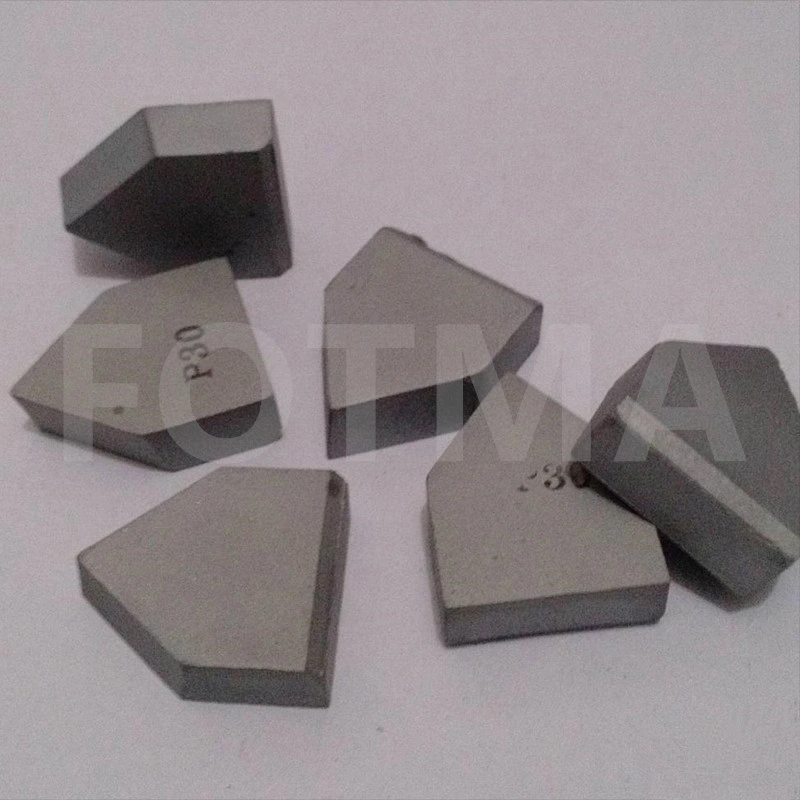

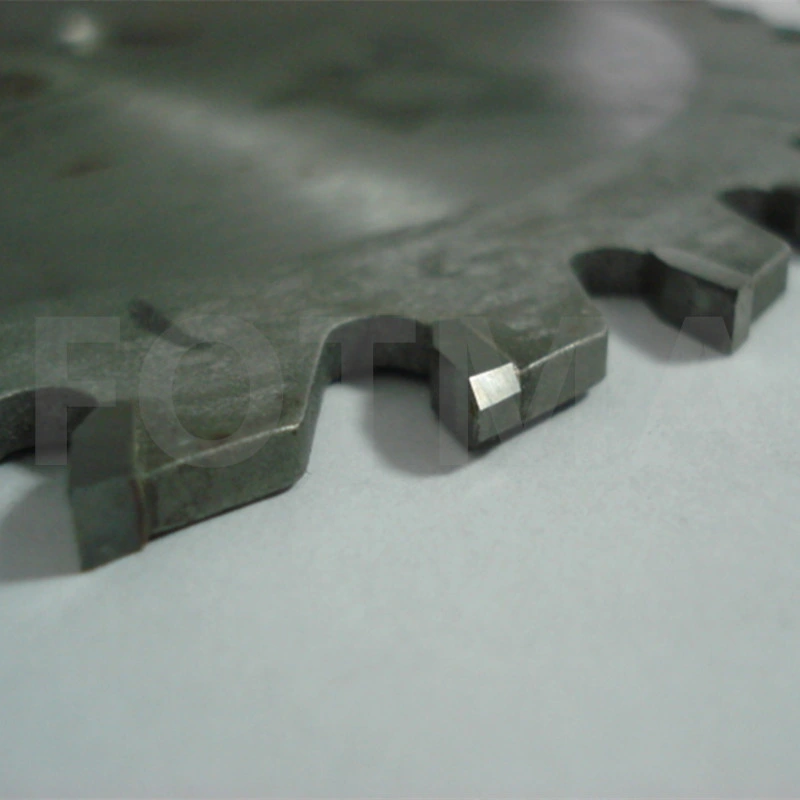

Carbide Cutting Tools

Fine grain alloy, good wear resistance, are offered with ground or blanks condition for processing hard wood, veneer board, PCB, PVC and metals cut glass, tile, paper, rubber and other kinds of materials. The edged discs are also available for cutting of stones, metals, electronic circuit boards and etc.

P20, P40 etc.

We supply tungsten carbide wear part, blanks, rod, plate, tips, saw tips, tools, blade, dies, tungsten carbide products. Please contact with our sales department for more details.

There are various sizes you can choose, and we can produce products according to your special designs and open mould in accordance with your requirements. Meanwhile there are various grades with different applications, so when you are going to purchase, please do not forget to inform what grade you need or what applications you want. Only in this way, we can judge and quote exactly on time.

Grade List for Tungsten Carbide Knife

Fine grain alloy, good wear resistance, are offered with ground or blanks condition for processing hard wood, veneer board, PCB, PVC and metals cut glass, tile, paper, rubber and other kinds of materials. The edged discs are also available for cutting of stones, metals, electronic circuit boards and etc.

P20, P40 etc.

We supply tungsten carbide wear part, blanks, rod, plate, tips, saw tips, tools, blade, dies, tungsten carbide products. Please contact with our sales department for more details.

There are various sizes you can choose, and we can produce products according to your special designs and open mould in accordance with your requirements. Meanwhile there are various grades with different applications, so when you are going to purchase, please do not forget to inform what grade you need or what applications you want. Only in this way, we can judge and quote exactly on time.

Grade List for Tungsten Carbide Knife

Grade | Density g/cm3 | Hardness HRA | Strength N/mm2 Min. | Applications | ISO grade |

YG6X | 14.8-15 | 91.7-93 | 1600 | High wear resistance and high strength; machining chilled cast iron and refractory steel, finishing of normal cast iron | K10(ANSI C-2) |

YT5 | 12.85-13.05 | 89.5-91 | 1700 | Excellent in strength, impact resistance and resistance to thermal shock; Rough turning, rough planning and semi planning of Carbon steel and alloy steel | P30(ANSI:C-5) |

YT15 | 11.2-11.4 | 92-93 | 1350 | Good wear resistance, with normal impact resistance; Semi finishing and finishing steel, cast steel, alloy steel. | P10 |

YT14 | 11.3-11.6 | 91.3-92.3 | 1450 | High in impact resistance and strength; Semi roughing and semi finishing of steel, cast steel and alloy steel. | P20-P30 |

YT535 | 12.6-12.8 | 90-91.5 | 1760 | High wear resistance and red hardness, high strength in use. For continuous rough turning and milling of cast or forged steel. | P30 |

ZP25 | 12.5-12.7 | 91.4-92.3 | 1750 | Fine in wear resistance and toughness; Rough turning, milling, planning and depth drilling of carbon steel, cast steel, manganese steel and alloy steel. | P20-P30 |

ZP35 | 12.6-12.8 | 90.5-91.5 | 1770 | A versatile grade, high in red hardness, strength and resistance to impact and thermal shocking. Roughing and strong cutting of steel and cast steel. | P30-P40 |

YG6 | 14.8-15 | 90-92 | 1650 | Good wear resistance, resistance to impact and thermal shocking. Semi finishing and finishing of cast iron, nonferrous metal, alloy and nonmetallic material. | K15-K20 |

YW1 | 13.25-13.5 | 92-93.2 | 1420 | A versatile grade, good in red hardness, able to endure normalimpact load; machining of refractory steel, high manganese steel, stainless steel, also suitable to the ormal steel and cast iron. | M10/P10 |

YW2 | 13.15-13.35 | 91.3-92.3 | 1600 | Good wear resistance and high strength, able to endure high impact load; Roughing, semi finishing of refractory steel, high manganese steel, stainless steel and high alloy steel, also suitable to the normal steel and cast iron. | M20/P20-30 |

ZM15 | 13.8-14.0 | 91-92.2 | 1720 | Good Red Hardness, high strength in use, capable of resisting high impact load. Finishing and semi-finishing of refractory steel, high manganese steel, and austenitic stainless steel, also suitable for Cast Iron. | M15 |

ZM30 | 13.5-13.7 | 90-91.5 | 1890 | High strength in use, capable of resisting high impact load. Roughing and semi-finishing of refractory steel, high manganese steel, stainless steel, etc. | M30 |

ZK10UF | 14.75-14.95 | 92.6-93.6 | 1690 | Fine-grained alloy, good wear resistance and high strength. Semi-finishing and finishing of cast iron and nonferrous metals. It is the unique material for making of solid carbide tools for holing. | K10-K15 |

ZK30UF | 14.3-14.55 | 91.2-92.2 | 2180 | Fine grain grade. Excellent wear resistance, high in strength and impact resistance. Machining of cast irons, nonferrous metals and non-metallic materials. It is the unique material of solid carbide tools for holing. | K30 |

Note: The specification dates just the standard, the actual specification for the products are much better than the standard. | |||||

Suggestion: We would like to recommend suitable grade depending on your machining materials. | |||||