Basic Info.

Model NO.

Various

Certification

ISO9001:2008

Coating

Uncoated

Material

Cemented Carbide

Shape and Dimensions

Customized

Chemical Composition

Co, W, Customized

Surface Quality

Ground or Polished

Delivery

About 25-30 Days

OEM

Offered

Transport Package

Customer Standard, Neutral Packing Available

Specification

ISO9001: 2000

Trademark

FOTMA

Origin

P. R. China

HS Code

81019910

Production Capacity

500t/Year

Product Description

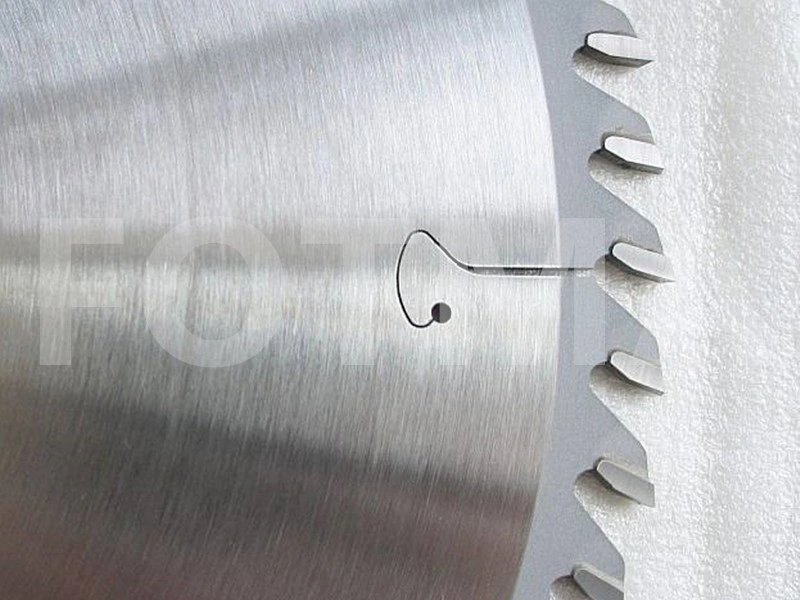

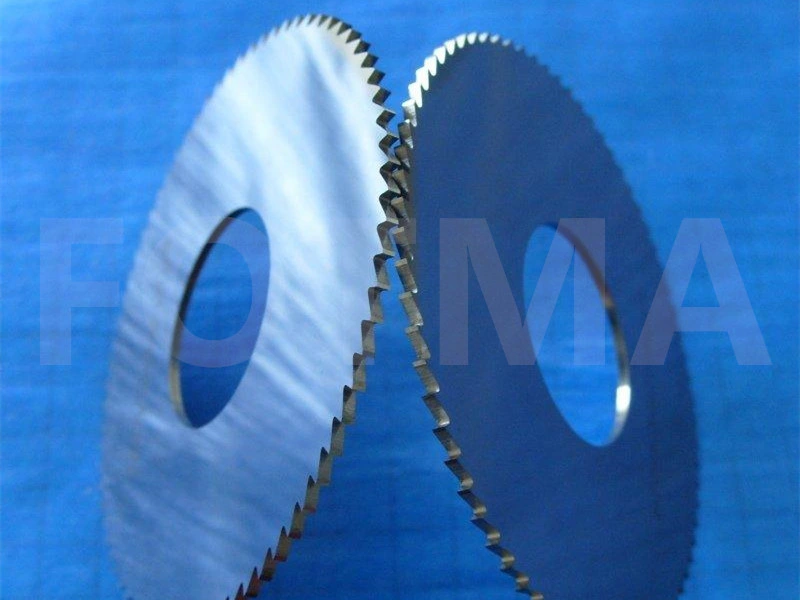

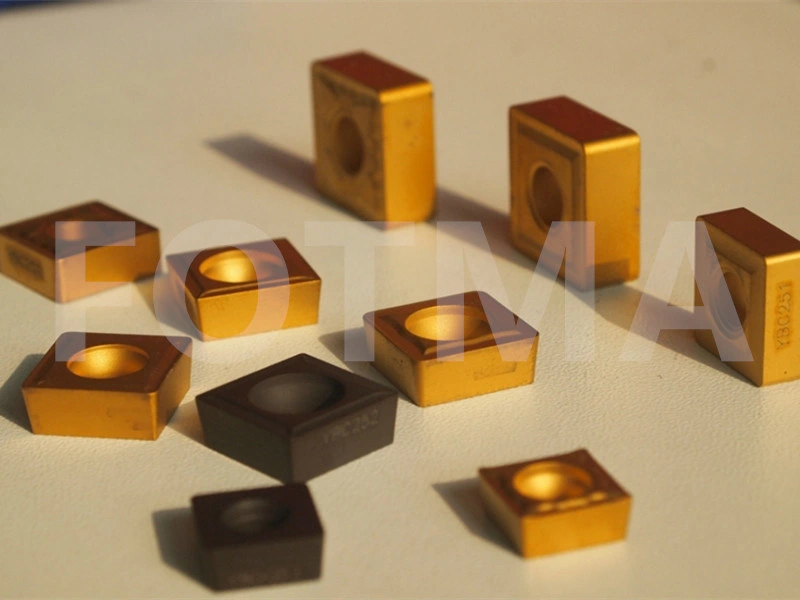

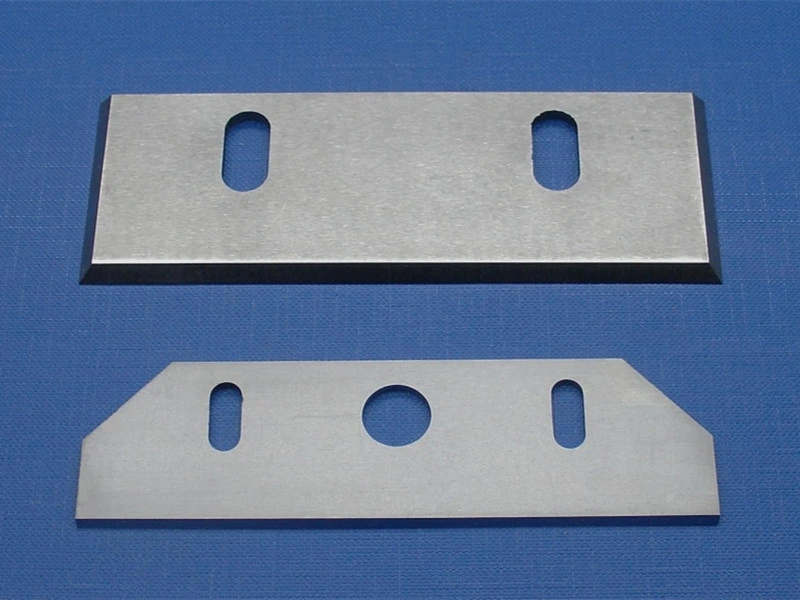

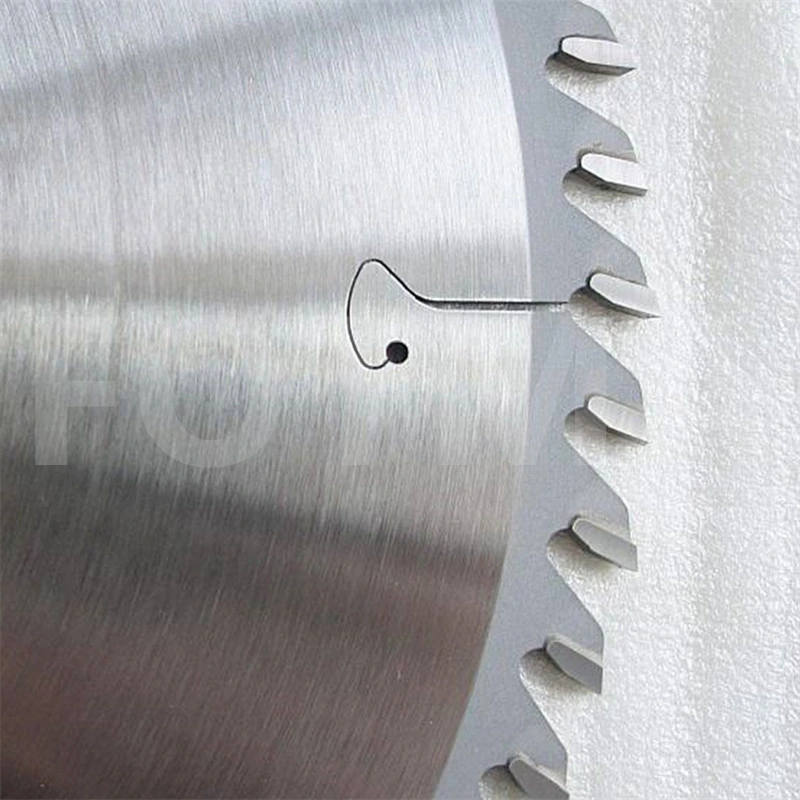

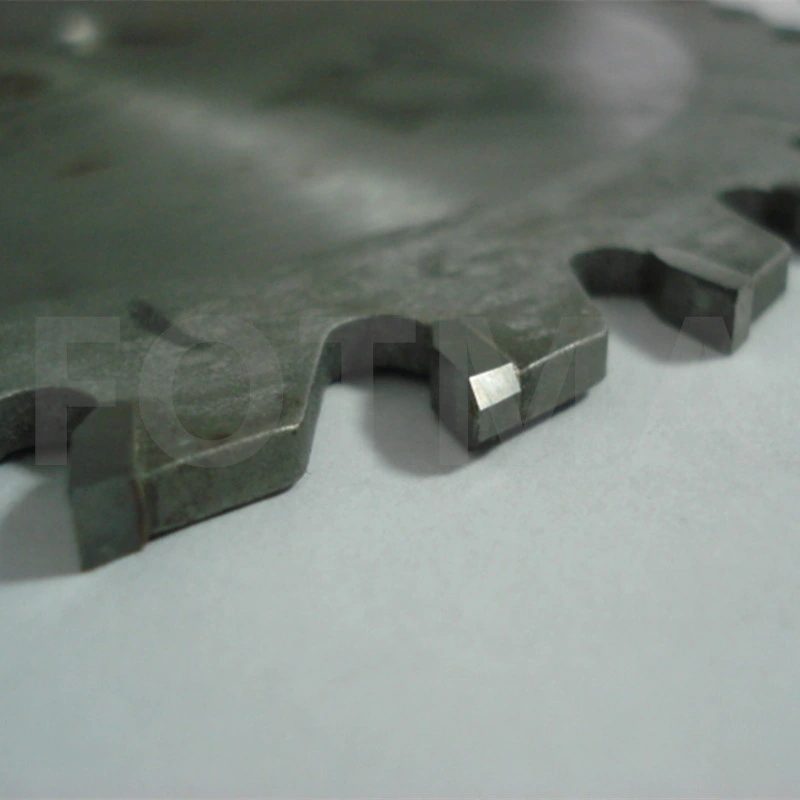

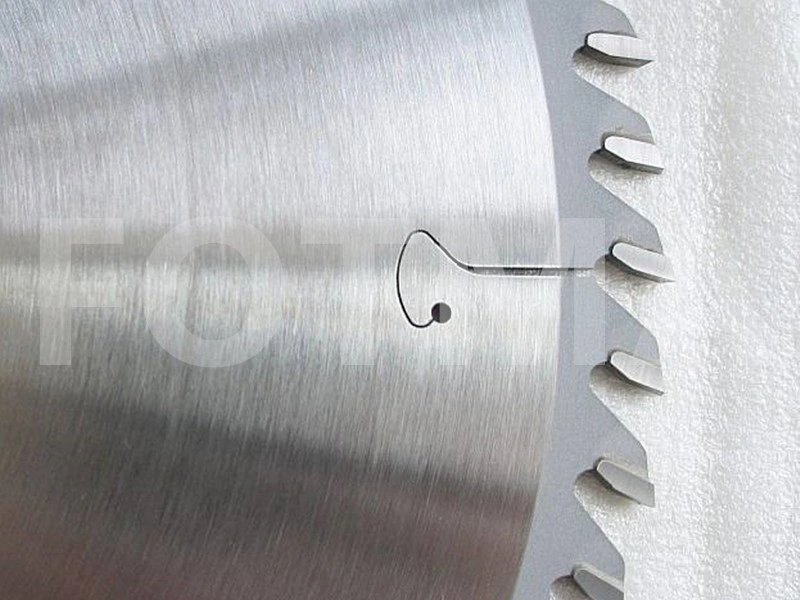

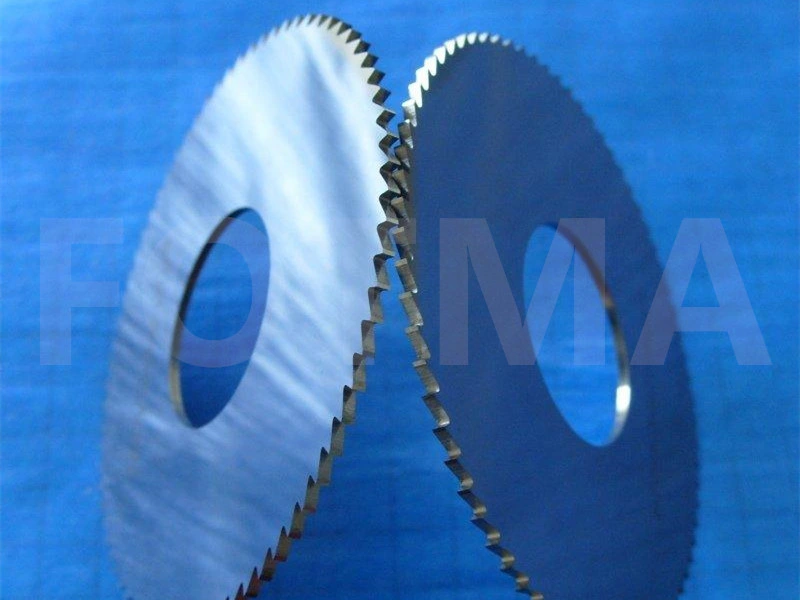

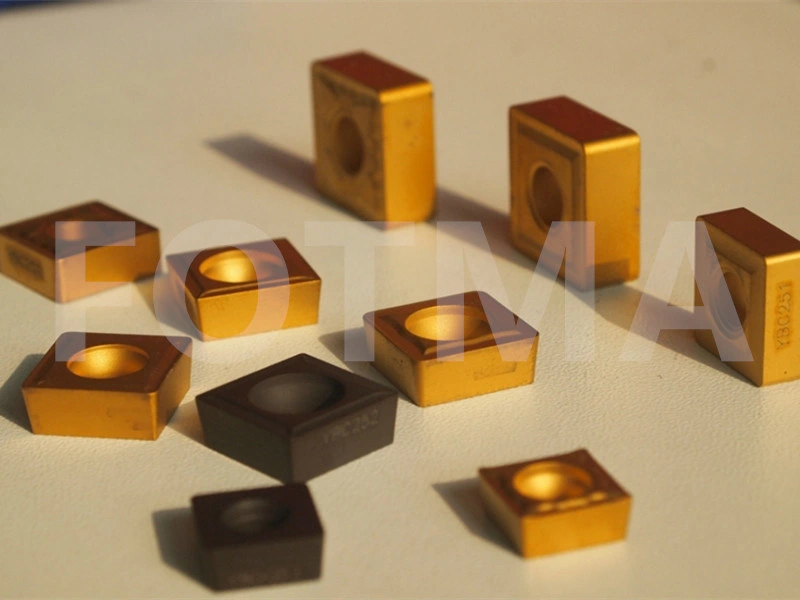

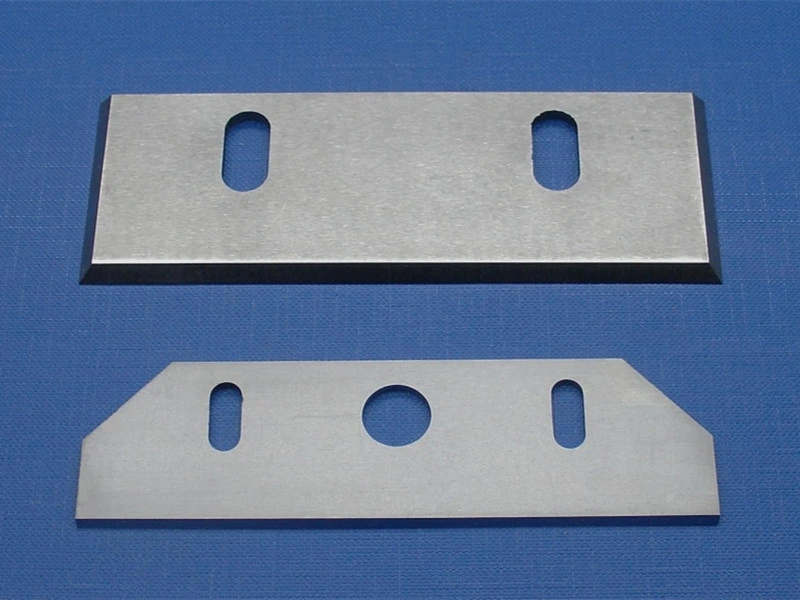

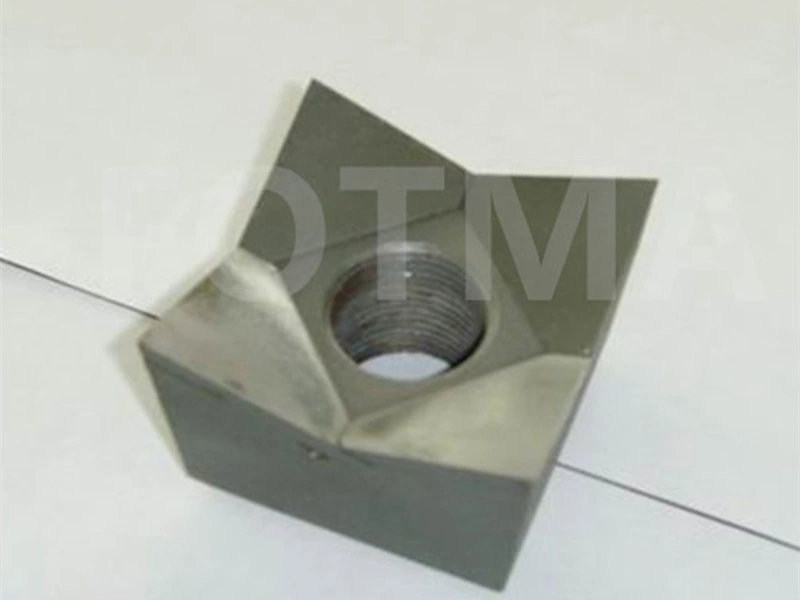

Tungsten Carbide metal cutting tools

Our company has in its possession an advanced production line for manufacturing dies and moulds and a production line for post machined cemented carbide products. We can also supply tailor-made products of various specifications based on the requirements of our customers.

Application:

Applied in aerospace, cars, horologe, cellphone, electron and medical apparatus and instruments.

We supply tungsten carbide insert, wear part, carbide blanks, tungsten carbide rod, carbide plate, carbide tips, carbide drill bits, tungsten carbide saw tips, carbide tools, carbide insert, carbide blade, carbide dies, carbide products. Please contact with our sales department for more details

Grade List for Tungsten Carbide Cutting Blades:

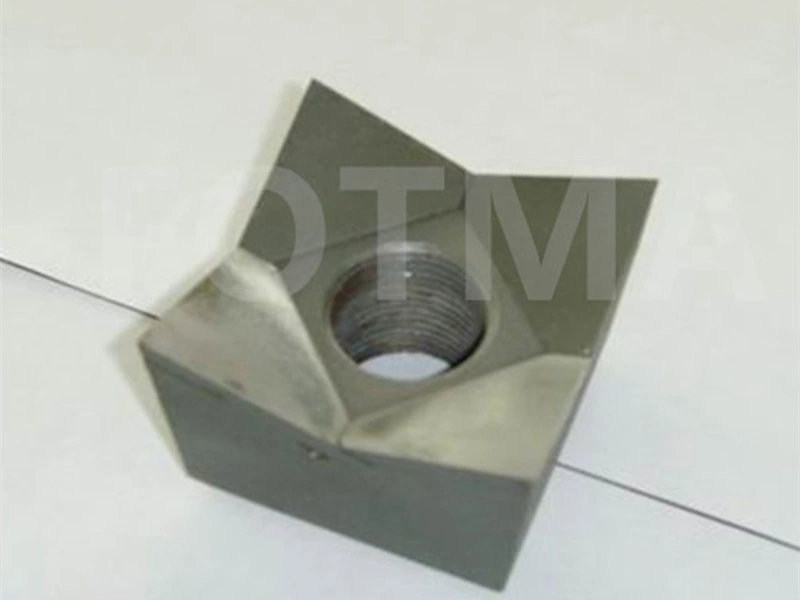

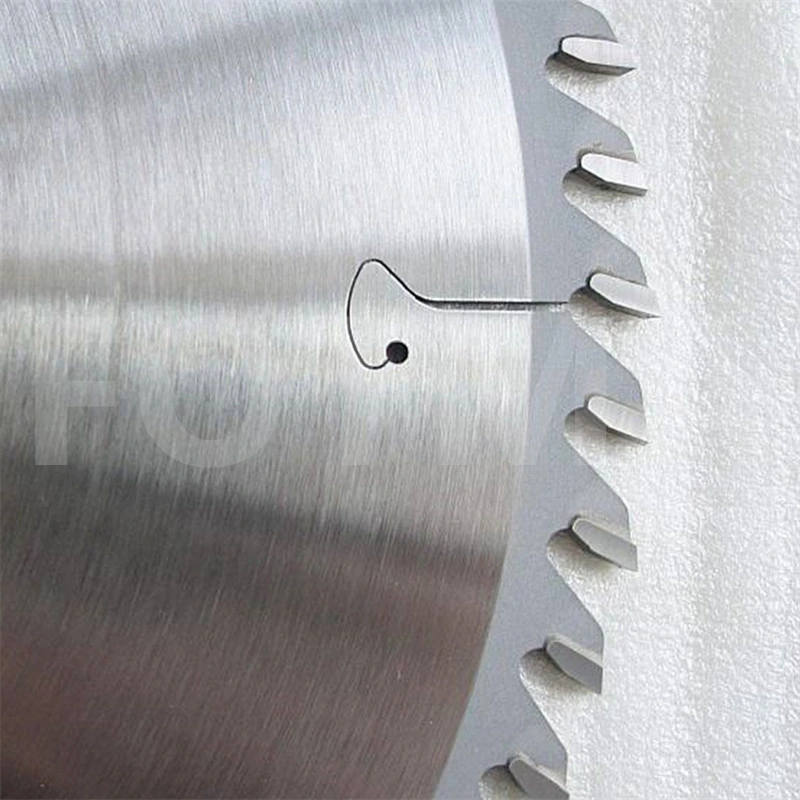

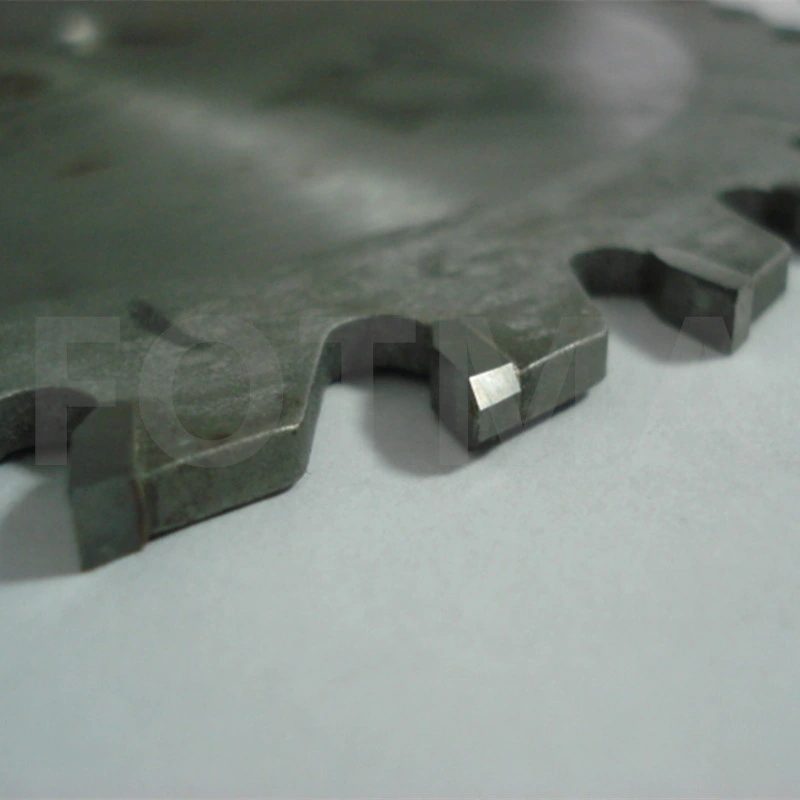

Product Show:

Our company has in its possession an advanced production line for manufacturing dies and moulds and a production line for post machined cemented carbide products. We can also supply tailor-made products of various specifications based on the requirements of our customers.

Application:

Applied in aerospace, cars, horologe, cellphone, electron and medical apparatus and instruments.

We supply tungsten carbide insert, wear part, carbide blanks, tungsten carbide rod, carbide plate, carbide tips, carbide drill bits, tungsten carbide saw tips, carbide tools, carbide insert, carbide blade, carbide dies, carbide products. Please contact with our sales department for more details

Grade List for Tungsten Carbide Cutting Blades:

Grade | ISO Grade | Density g/cm3 | Hardness HRA≥ | Bending strength≥N/mm² | Application |

YG3 | K05 | 15.20-15.40 | 91.5 | 1400 | Medium grain size, suitable for the cast iron and the non-ferrous metal precision work. |

YG3X | K05 | 15.20-15.40 | 92 | 1300 | Small grain size, suitable for the cast iron and the non-ferrous metal precision work. |

YG4C | 15.05-15.25 | 90 | 1620 | ||

YG6 | K20 | 14.85-15.05 | 90.5 | 1860 | Medium grain size, used for the non-ferrous metal the rough machining |

YG6A | K10 | 14.85-15.05 | 92 | 1600 | Small grain size, suitable for the wiredrawing mold and the woodworking tool |

YG6X | K10 | 14.85-15.05 | 91.7 | 1800 | Small grain size, suitable for non-ferrous metal cutting |

YG7 | K20 | 14.65-14.85 | 89.7 | 1900 | Grain alloy, good resistance to wear and good anti-shocking |

YG8 | K30 | 14.60-14.85 | 90 | 2060 | Medium grain size, suitable for the wiredrawing mold, draws the mold |

YG8A | K30 | 14.6-14.85 | 90 | 2000 | Medium grain size, suitable for the wiredrawing mold, draws the mold, woodworking blade and so on |

YG8X | K30 | 14.60-14.85 | 90.5 | 2000 | Small grain alloy, high temperature degree of hardness, oxidation resistance and the anti-resilience |

YG8C | 14.55-14.75 | 88 | 2160 | Macro grain size, suitable for the ball tooth rock drill and the mine rock drill piece | |

YG10 | K40 | 14.25-14.55 | 88 | 2160 | Medium grain size, suitable for processing the low hard gray cast iron |

YG11 | K40 | 14.30-14.50 | 87.5 | 2260 | Medium grain size, suitable for the wear-resisting components and the mine tool |

YG11C | 14.20-14.40 | 87 | 2260 | Macro grain size, is suitable for the mine rock drill piece | |

YG12 | K40 | 14.10-14.40 | 87 | 2260 | Medium grain size, suitable for the non-ferrous metal rough machining |

YG15 | 13.95-14.15 | 87 | 2400 | Medium grain size, is suitable for the mine tool and dies | |

YG20 | 13.45-13.65 | 84 | 2480 | Medium grain size, suitable for dies | |

YG20C | 13.40-13.60 | 82.5 | 2480 | Macro grain size, used for diameter 20-50mm the die mold |

Product Show: