Basic Info.

Model NO.

MG NCC 1/2

Trademark

MG

Origin

Suzhou

HS Code

8455300000

Production Capacity

30000t/Y

Product Description

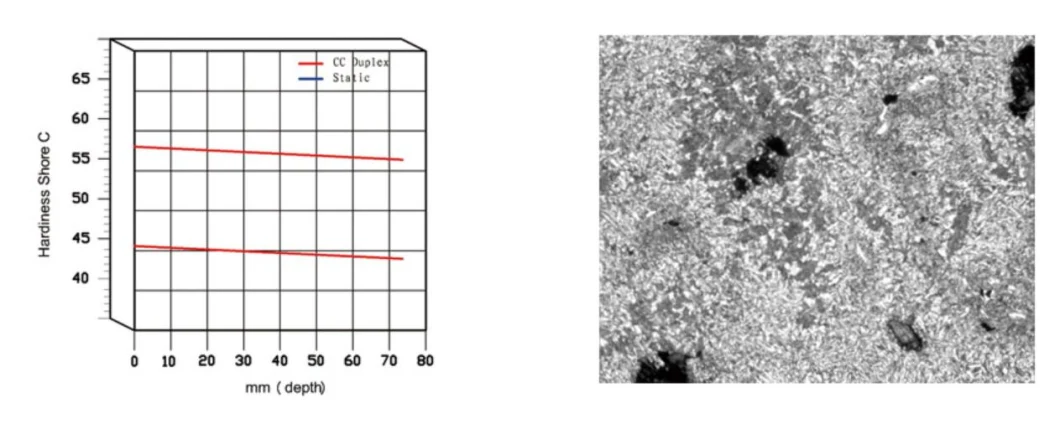

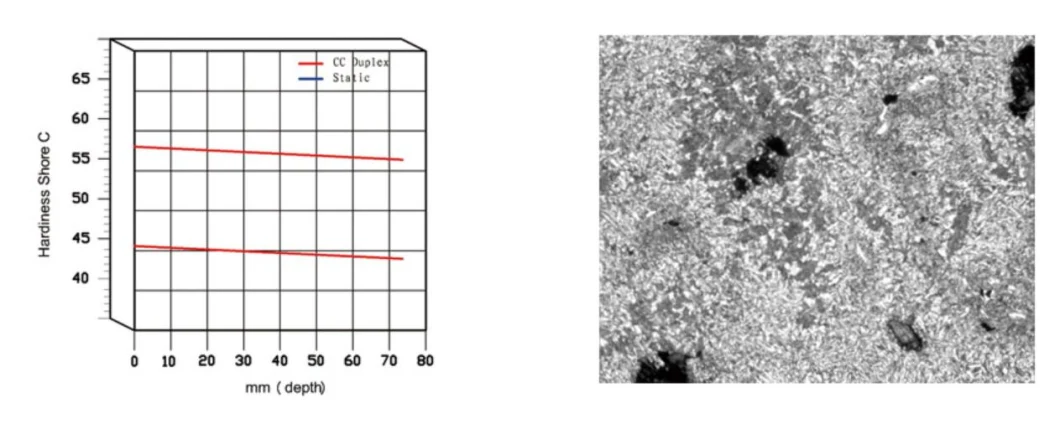

Rolls for roughers require a combination of some properties, some of which can be counteracted by the others. These properties include wearability, resistance of fire cracking and impact, hot hardness and hot strength etc. Excessive network carbides will improve wearability and impact resistance but dramatically reduce fracture toughne ss. Under rough rolling process they can promote fire cracking formation and added to form Bainitic/Martensite (acicular) matrix, which is more wearable than conventional pearlitic matrix. The Molybdenum can also improve the hot hardness of rolls. The type of roll is manufactured from high alloy materials with special heat treatment. Carbide content in the matrix is less than 5%, which is satisfactory to the requirement of roughers.

Product Parameter

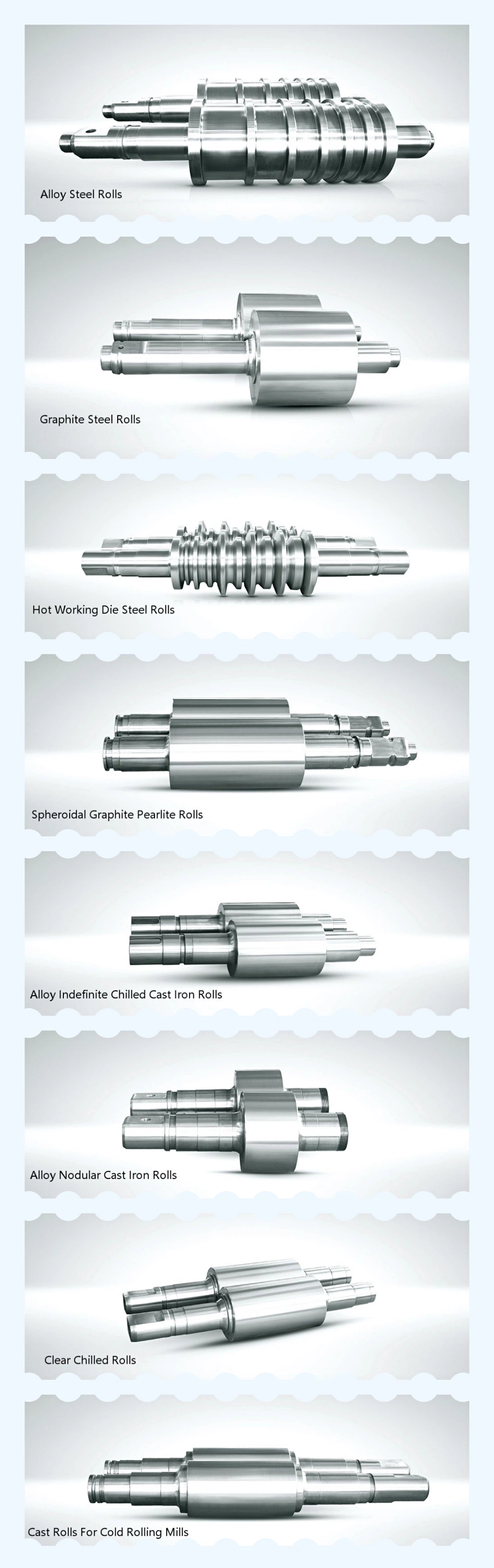

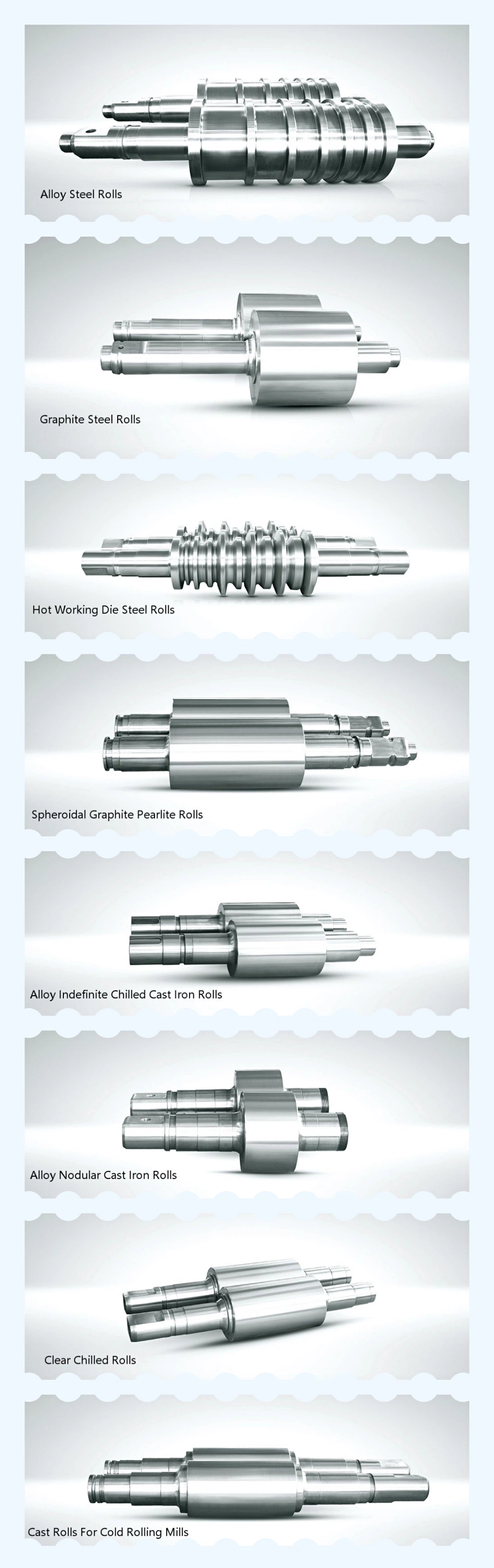

OTHER MOLDS

APPLICATION

PACKING & SHIPPING

ABOUT US

Product Parameter

| Chemical Composition % | ||||||

| symbol | C | Si | Mn | Cr | Ni | Mo |

| MG NCC 1 | 3.00-3.40 | 2.00-2.50 | 0.80-1.00 | ≥0.15 | 2.00-3.00 | 0.40-0.70 |

| MG NCC 2 | 3.00-3.40 | 1.50-2.00 | 0.80-1.00 | ≥0.15 | 2.50-4.50 | 0.50-1.00 |

| Properties And Application % | ||||||

| Symbol | Hardness HS | Tensile strength MPa | Bending strength MPa | Dimension | Unit Weight Kg | Application |

| MG NCC 1 | 40-50 | ≥520 | 970-1380 | φ500-1380 | 1000-35000 | Roughing stands of bar and wire mills, BD2 rolls for large section. |

| MG NCC 2 | 50-60 | ≥520 | 970-1380 | |||

OTHER MOLDS

APPLICATION

PACKING & SHIPPING

ABOUT US

We sincerely welcome our honored guests to our company for inspection and cooperation!