- Overview

- Product Description

- Workshop Show

- Certifications

- Packaging & Shipping

Basic Info.

Product Description

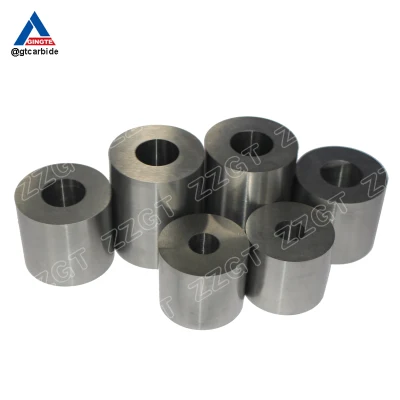

Tungsten carbide die blanks are widely used for making finished die casting mould, punch dies, wire drawing die, machine mold, progressive die, extrusion die, press mold, mould parts, trimming die, cold heading die, forging mold, cold forming die etc.

Gingte has the most wide and stable grades for carbide dies and has highest cost performance.

If you are intetested in our products , please contact us freely.

we have complete manfacturing line and advanced complete equipments. From pressing , blank to fine manufacturing , we can do it.

In mixing powder processsure, we have spray drawing tower, over 20 sets mixed balling machine. Variouse Tons pressing machines are avaible in our company. It means that we can produce many kinds of shape blank.

Our comoany has a variety of advanced rough blank and finishing production equipment including but not limited to vacuum sintering furnace, internal and extrernal cylindrical grinders, surface grinders, Electronical Spark machine, EDM,CNC cutting machines,molding machines ,etc

Our products are also widely used in oil&gas drilling ,exploitation and chemical industry, coal chemical industry, pump valve, advanced material and other industries. The main products include wear resistance parts of measurement while drilling, wear resistant parts of hydraulic oscillators, wear resistant parts of wellhead equipments, threaded nozzles, fracturing nozzles, PDC/TC bearings, disc valves, and angle valves,etc.

Items Tungsten carbide wear parts to be packed suitably for Express, sea freight, train freight and road freight.

Items Cemented Carbide wear parts to be placed into plastic box or paper box or buckets. Each bucket/box not exceed 25KG. These are to be labelled using customer provided label, put ont to a pallet and the pallets to be completely enclosed with wood.

If you have special package demands, pls tell our sales engineer.