Basic Info.

Model NO.

W1/W2/WAl1/WCe0.8/WCe1.1/WCe1.6/WCe2.4/WCe3.2

Process

Cold Rolled

MOQ

200kgs

Delivery Time

10-20 Days

Transport Package

as Your Requirements

Specification

0.1-10mm

Trademark

HUICHI

Origin

China

HS Code

8101991000

Production Capacity

1000000tons/Year

Product Description

Product Description

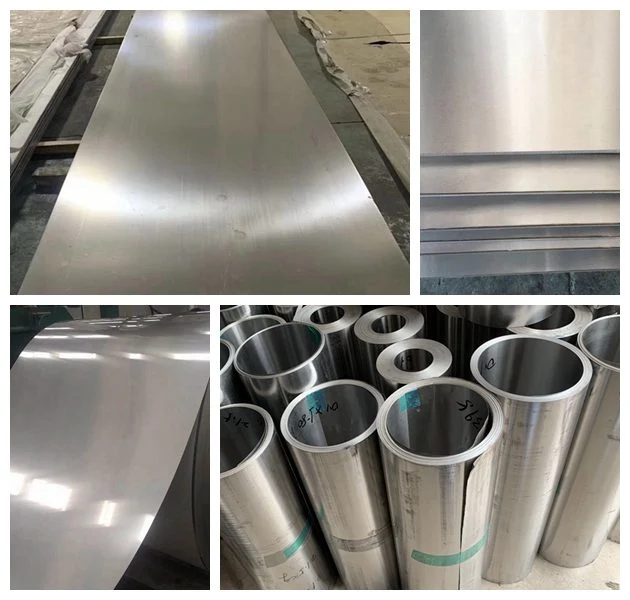

1. tungsten bar/tungsten rod/tungsten wire

2. Material Grade:Mo1/Mo2/MoW20/MoW30/MoW50

3.Standard: ASTM BS JIS NF DIN GB

4.Thickness: 0.1-10mm

5. Width:up to 1000mm

6.Process: cold rolled,hot rolled

The melting point of tungsten is the highest among all metals and the hardness is also high, so it is often used to produce heat-strength and wear-resistant alloys.

Because of its high density and high hardness, tungsten has become an ideal material for making high-density alloys. These high-density alloys are classified into W-Ni-Fe, W-Ni-Cu, W-Co, and W-WC according to their composition characteristics and uses. -Cu, W-Ag and other main series. These alloys have the characteristics of high specific gravity, high strength, strong radiation absorption ability, large thermal conductivity, small thermal expansion coefficient, good electrical conductivity, good solderability and processability, etc., and are widely used In aerospace, aviation, military, oil drilling, electrical instrumentation, medicine and other industries, such as manufacturing armor, heat sinks, counterweights for rudder control, and contact materials such as knife switches, circuit breakers, spot welding electrodes, etc.

Application

1.Electronic field

2.Chemical industry

3.Aerospcae

4.Aviation

5.Military

6.Oil Drilling

7.Medicine

Certification

Certification

Application

Application

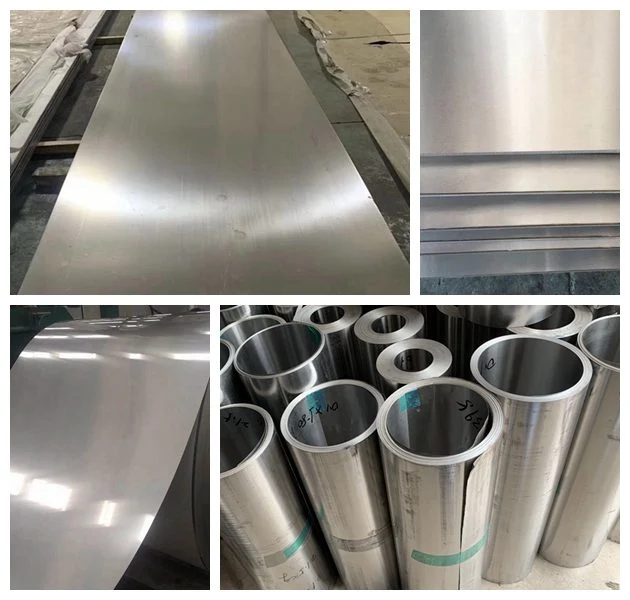

1. tungsten bar/tungsten rod/tungsten wire

2. Material Grade:Mo1/Mo2/MoW20/MoW30/MoW50

3.Standard: ASTM BS JIS NF DIN GB

4.Thickness: 0.1-10mm

5. Width:up to 1000mm

6.Process: cold rolled,hot rolled

The melting point of tungsten is the highest among all metals and the hardness is also high, so it is often used to produce heat-strength and wear-resistant alloys.

Because of its high density and high hardness, tungsten has become an ideal material for making high-density alloys. These high-density alloys are classified into W-Ni-Fe, W-Ni-Cu, W-Co, and W-WC according to their composition characteristics and uses. -Cu, W-Ag and other main series. These alloys have the characteristics of high specific gravity, high strength, strong radiation absorption ability, large thermal conductivity, small thermal expansion coefficient, good electrical conductivity, good solderability and processability, etc., and are widely used In aerospace, aviation, military, oil drilling, electrical instrumentation, medicine and other industries, such as manufacturing armor, heat sinks, counterweights for rudder control, and contact materials such as knife switches, circuit breakers, spot welding electrodes, etc.

Application

1.Electronic field

2.Chemical industry

3.Aerospcae

4.Aviation

5.Military

6.Oil Drilling

7.Medicine

| W | Ce | Th | Re | Ca | Fe | Mg | Mo | Ni | Si | C | N | Other | |

| W1 | balcance | 0.003 | 0.005 | 0.002 | 0.01 | 0.003 | 0.003 | 0.005 | 0.003 | Al0.002 O0.005 | |||

| W2 | balcance | 0.003 | 0.005 | 0.002 | 0.01 | 0.003 | 0.005 | 0.008 | 0.003 | Al0.004 O0.008 | |||

| WAl1/WAl2 | balcance | 0.005 | 0.005 | 0.005 | 0.01 | 0.005 | 0.005 | 0.003 | |||||

| WCe0.8 | balcance | 0.65-0.98 | 0.005 | 0.005 | 0.005 | 0.01 | 0.003 | 0.005 | 0.01 | 0.003 | |||

| WCe1.1 | balcance | 1.06-1.38 | 0.005 | 0.005 | 0.005 | 0.01 | 0.003 | 0.005 | 0.01 | 0.003 | |||

| WCe1.6 | balcance | 1.47-1.79 | 0.005 | 0.005 | 0.005 | 0.01 | 0.003 | 0.005 | 0.01 | 0.003 | |||

| WCe2.4 | balcance | 2.28-2.6 | 0.005 | 0.005 | 0.005 | 0.01 | 0.003 | 0.005 | 0.01 | 0.003 | |||

| WCe3.2 | balcance | 3.09-3.42 | 0.005 | 0.005 | 0.005 | 0.01 | 0.003 | 0.005 | 0.01 | 0.003 | |||

| WTh0.7 | balcance | 0.6-0.84 | 0.005 | 0.005 | 0.01 | 0.003 | 0.01 | 0.003 | |||||

| WTh1.1 | balcance | 0.85-1.27 | 0.005 | 0.005 | 0.01 | 0.003 | 0.01 | 0.003 | |||||

| WTh1.5 | balcance | 1.28-1.7 | 0.005 | 0.005 | 0.01 | 0.003 | 0.01 | 0.003 | |||||

| WTh1.9 | balcance | 1.7-2.13 | 0.005 | 0.005 | 0.01 | 0.003 | 0.01 | 0.003 | |||||

| WRe1.0 | balcance | 0.9-1.1 | 0.005 | 0.005 | 0.01 | 0.003 | 0.01 | 0.003 | |||||

| WRe3.0 | balcance | 2.85-3.15 | 0.005 | 0.005 | 0.01 | 0.003 | 0.01 | 0.003 |

Certification

Certification Application

Application