Basic Info.

Model NO.

OD14*ID9.0*T4.0mm

Customized

Non-Customized

Material

Tungsten Carbide

Application

Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Grade

Yg8

Hardness

89.5hra

Density

14.8g/cm3

T.R.S

2600MPa

Usage

as Baffle Loop

Outdiameter

14mm

Inner Diameter

9.0

Thickness

4.0

Transport Package

25kg. Carton

Specification

OD14*ID9.0*T4.0mm

Trademark

ZZUP

Origin

Zhuzhou, Hunan, China

HS Code

820900100

Production Capacity

10000000PCS/Month

Product Description

8% Co OD14*ID9.0*T4.0mm polished tungsten carbide baffle loop

8% Co OD14*ID9.0*T4.0mm polished tungsten carbide baffle loop

Specifications

1. Grade: YG8 , Density 14.8g/cm3,

2. YG8,YG6,YG3,YG10,YG15,YT14,YT5,YT05,YT15,YG20,YG25,YL10.2,YS2T,YG6X etc all kinds of grades for your choose.

3. Can product customize drawing,sizes and shape.

8% Co OD14*ID9.0*T4.0mm polished tungsten carbide baffle loop

Specifications

1. Grade: YG8 , Density 14.8g/cm3,

2. YG8,YG6,YG3,YG10,YG15,YT14,YT5,YT05,YT15,YG20,YG25,YL10.2,YS2T,YG6X etc all kinds of grades for your choose.

3. Can product customize drawing,sizes and shape.

Products Show

Grades choosing

Common grades for all kinds metal

Grades for cold mill roll or hot mill roll steel

Other grades and sizes can be offered as per customers' requirements

Common grades for all kinds metal

| Grade | Density g/cm3 | Hardnes HRA | T.R.S Mpa | Performance&application recommended |

| YG6A | 14.85 | 92.5 | 2000 | Fine grain alloy,good wear resistance.it is suitable for manufacturing forming cutter,wear-resistant parts etc. |

| YG8 | 14.7 | 89.8 | 2800 | High bending strength,wear resistance lower than YG6A, suitable for manufacturing cutter ,wear-resistant parts etc. |

| YG11 | 14.4 | 88.5 | 2900 | High bending strength,wear resistance lower than YG6A, suitable for manufacturing cutter ,wear-resistant parts etc. |

| YG15 | 14.0 | 87.0 | 3000 | Suitable for manufacturing punching dies, wear-resistant parts. |

| YG20 | 13.5 | 85.5 | 2800 | High bending strength,suitable for manufacturing progressive dies and other punching dies. |

| YG25 | 13.1 | 81.5 | 2950 | High bending strength,wear resistance lower than YM6A, suitable for manufacturing cutter ,wear-resistant parts etc. |

| YS2T | 14.25 | 92.0 | 2500 | Fine grain alloy, with high wear resistance, bending strength, bonding resistance and thermal strength. it is suitable for machining refractory alloys,stainless steel, high manganese steel, etc. |

Grades for cold mill roll or hot mill roll steel

| Grade | Wc (%) | Co (%) | Ni (%) | Cr (%) | Density g/cm3 | Hardness ≥HRA | T.R.S ≥Nmm2 | Compression Strength ≥Nmm2 | Thermal Expansivity 10-6/K | Thermal Conductivity W/cm.k | Young's Elastic Modulus KN/mm2 |

| YGR60 | 70 | 30 | 12.8 | 78 | 2200 | 2900 | 7 | ||||

| YGR55 | 76 | 24 | 13.1 | 80 | 2400 | 3000 | 6.8 | 0.17 | 420 | ||

| YGR45 | 80 | 20 | 13.5 | 81 | 2500 | 3100 | 6.4 | 0.14 | 480 | ||

| YGR40 | 82 | 18 | 13.7 | 82.5 | 2600 | 3200 | 6.2 | 0.2 | 530 | ||

| YGR30 | 85 | 15 | 14.2 | 84.8 | 2700 | 3300 | 6.1 | 0.2 | 530 | ||

| YGR25 | 88 | 12 | 14.3 | 85 | 2600 | 3400 | 6 | 0.2 | 550 | ||

| YGH55 | 74 | 26 | 12.9 | 80 | 2200 | 3000 | 7 | 0.17 | 450 | ||

| YGH45 | 75 | 25 | 13.4 | 82 | 2400 | 3100 | 6.5 | 0.18 | 480 | ||

| YGH40 | 82 | 18 | 13.6 | 83.5 | 2500 | 3200 | 6.4 | 0.19 | 500 | ||

| YGH30 | 85 | 15 | 13.9 | 83.5 | 2400 | 3300 | 6.1 | 0.2 | 540 | ||

| YGH25 | 88 | 12 | 14.1 | 85 | 2300 | 3400 | 6 | 0.2 | 560 |

Common sizes:

Other sizes can be offered as per customers' requirements

| Outdiameter (mm) | Inner diameter (mm) | Height (mm) | Outdiameter (mm) | Inner diameter (mm) | Height (mm) | |

| 90 | 51 | 4~100 | 125 | 45 | 4~100 | |

| 90 | 20 | 125 | 80 | |||

| 90 | 3 | 130 | 40 | |||

| 95 | 75 | 130 | 50 | |||

| 95 | 68.5 | 140 | 90 | |||

| 95 | 74 | 142 | 78 | |||

| 100 | 65 | 150 | 90 | |||

| 100 | 62.1 | 160 | 80 | |||

| 100 | 20 | 161 | 108 | |||

| 105 | 46 | 212 | 120 | |||

| 105 | 65.5 | 158.8 | 87.32 | |||

| 105 | 81 | 170.66 | 95 | |||

| 105 | 75 | 180 | 87.32 | |||

| 110 | 20 | 180 | 120.65 | |||

| 110 | 30 | 228.3 | 126 | |||

| 110 | 90 | 208 | 126 | |||

| 114 | 94 | 228 | 130 | |||

| 115 | 65 | 285 | 160 | |||

| 115 | 60 | 320 | 260 | |||

| 120 | 46 | 280 | 240 | |||

| 120 | 65 | 318 | 280 | |||

| 120 | 60 | 600 | 550 | |||

| 125 | 45 | 800 | 200 |

Other sizes can be offered as per customers' requirements

Packing details

Shipping ways

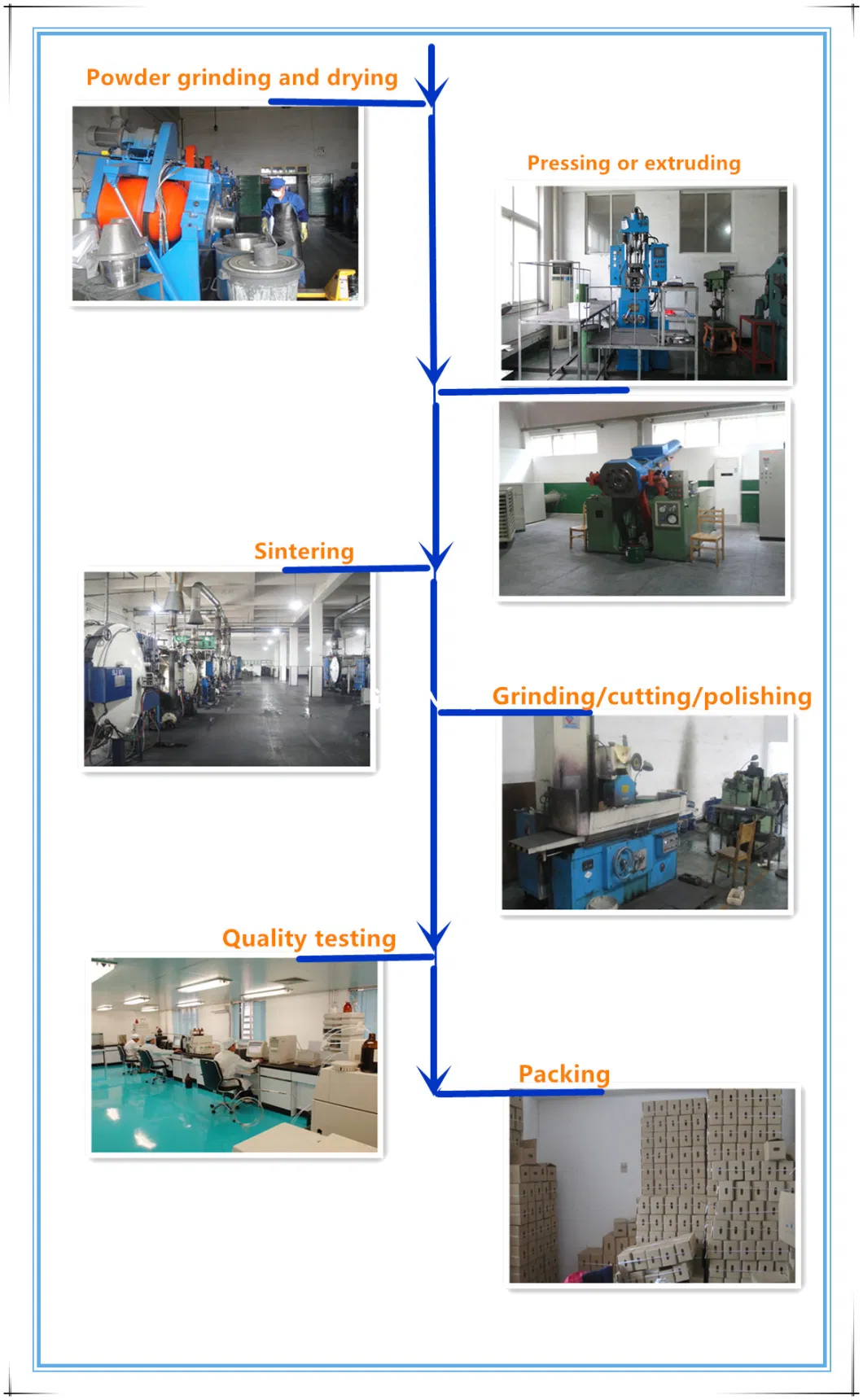

Production process

Contact details