Basic Info.

Model NO.

JX10535-W5.5

Thickness

3.5mm

Width

5.5mm

Transport Package

Bottled and Carton

Specification

JX10535-W5.5

Trademark

ZZUP

Origin

Zhuzhou Hunan

Product Description

91.5HRa/92.5HRa/93.5HRa hardness tungsten carbide saw tooth

91.5HRa/92.5HRa/93.5HRa hardness tungsten carbide saw tooth

Products description

1. Grades: YG6X,YG6,YG8,YG8X,JX10,JX15,JX35,JX40 etc

2. the saw tips include F series, US Standard and European Standard.

3. All saw tips are HIP-Sintered, to make sure high quality, with automatic pressing to make sure accurate size, tumble and nickel covered to make sure good brazing performance.

4. Our brand has gain reputation from clients in Europe, USA, Asia, etc.

5. Our grades cover all ISO range, suitable to cut grass, hard wood, recycle wood, metal, plastic, PVC, MDF,

Melamine board, plywood, etc.

Products Show

Grade specification

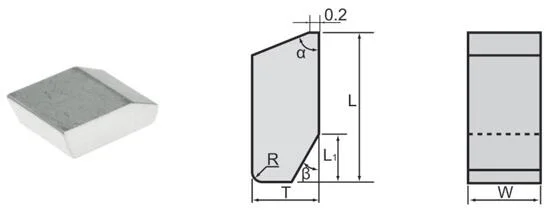

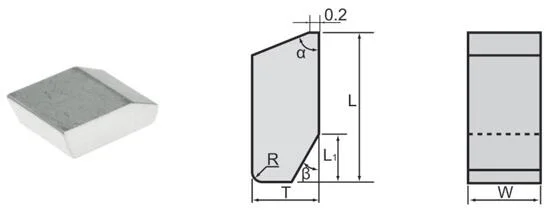

Drawing and sizes

Packing details

Shipping ways

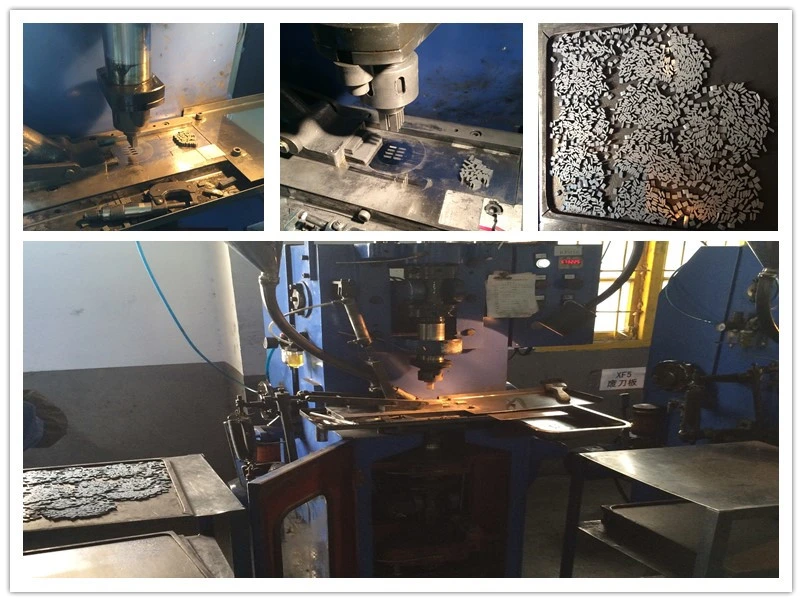

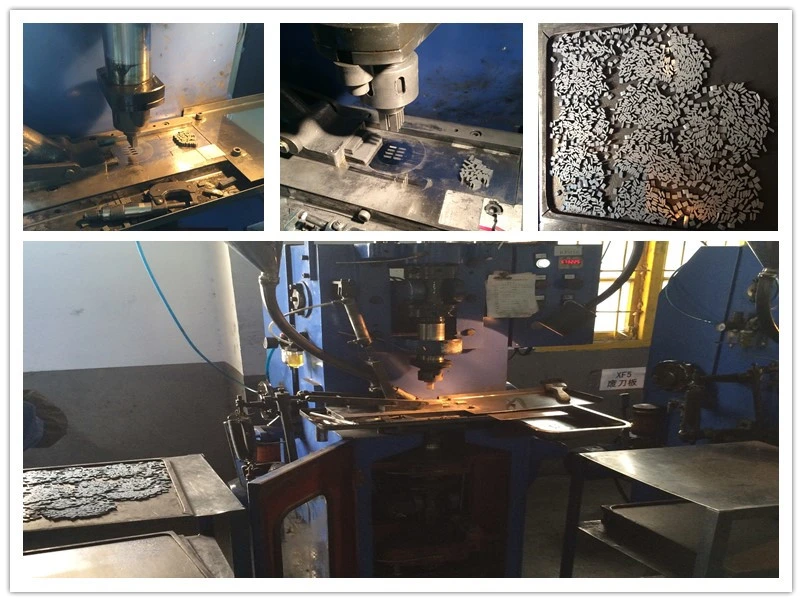

Production process

91.5HRa/92.5HRa/93.5HRa hardness tungsten carbide saw tooth

Products description

1. Grades: YG6X,YG6,YG8,YG8X,JX10,JX15,JX35,JX40 etc

2. the saw tips include F series, US Standard and European Standard.

3. All saw tips are HIP-Sintered, to make sure high quality, with automatic pressing to make sure accurate size, tumble and nickel covered to make sure good brazing performance.

4. Our brand has gain reputation from clients in Europe, USA, Asia, etc.

5. Our grades cover all ISO range, suitable to cut grass, hard wood, recycle wood, metal, plastic, PVC, MDF,

Melamine board, plywood, etc.

Products Show

Grade specification

| Grade | Density (g/cm³) | Hardnes (HRA) | T.R.S(Mpa) | ISO Code | Application recommended | Proposal for welding | |

| YG6 | 14.6~15.0 | ≥90.0 | ≥1800 | K20 | Applying to the cutting of ordinary wood | For resistance welding, and the temperature should not be too high | |

| YG8 | 14.6~14.9 | ≥89.5 | ≥1900 | K30 | For the cutting of ordinary wood & aluminum material | For resistance welding, and the temperature should not be too high | |

| JX5 | 14.6~15.0 | ≥90.5 | ≥1900 | K10 | Applies to the cutting of hard wood,recyling wood and aluminum alloy material | For resistance welding,and the temperature should not be too high | |

| JX9 | 14.5~14.9 | ≥90.5 | ≥2000 | K10 | Applying to the cutting of aluminum copper and lead,non-ferrous alloy material | Recommend the high-frequency welding | |

| YG6X | 14.7~15.0 | ≥91.5 | ≥1800 | K10 | Applying to the cutting of the timber | Recommend the high-frequency welding | |

| JX10 | 14.8~15.1 | ≥93.3 | ≥2500 | K05 | Applying to the cutting of hard wood ,also soft metal | Recommend the high-frequency welding | |

| JX15 | 14.6~15.0 | ≥92.5 | ≥2400 | K05 | Applying to the cutting of hardwood and aluminum alloy | Recommend the high-frequency welding | |

| JX35 | 14.9~15.2 | ≥93.5 | 2000 | K10 | Applying to the cutting of plywood mdf board and sandwich board | Recommend the high-frequency welding | |

| JX40 | 12.8~13.2 | ≥90.5 | ≥2000 | P40 | Applying to the cutting of seel | Recommend the high-frequency welding | |

Drawing and sizes

| TYPE | Dimension(mm) | |||||

| L | T | W | α° | β° | R | |

| JX4125 | 4.2 | 1.5 | 2.7 | 30 | 20 | 0.5 |

| JX4514 | 4.5 | 1.4 | 3.0 | 28 | 15 | 0.6 |

| JX4515 | 4.5 | 1.5 | 3.5 | 30 | 27 | 0.5 |

| JX4615 | 4.6 | 1.5 | 3.6 | 30 | 26.6 | 0.5 |

| JX4713 | 4.7 | 1.3 | 3.4 | 33 | - | 0.5 |

| JX4715 | 4.7 | 1.5 | 3.7 | 30 | 30 | 0.5 |

| JX4816 | 4.8 | 1.6 | 3.5 | 30 | 17 | 0.5 |

| JX5014 | 5.0 | 1.4 | 3.5 | 30 | 15 | 0.5 |

| JX5014A | 5.0 | 1.4 | 3.5 | 20 | 25 | 0.5 |

| JX5015 | 5.0 | 1.5 | 3.5 | 20 | 20 | 0.5 |

| JX5015A | 5.0 | 1.5 | 4.0 | 30 | 26.5 | 0.5 |

| JX5015B | 5.0 | 1.5 | 4.5 | 20 | 45 | 0.5 |

| JX5015C | 5.0 | 1.5 | 3.6 | 30 | 0.5×45° | - |

| JX5016 | 5.0 | 1.6 | 4.0 | 30 | 22 | 0.5×45° |

| JX5016A | 5.03 | 1.63 | 4.5 | 25 | 0.7×45° | 0.5 |

| JX5016B | 5.0 | 1.6 | 3.6 | 20 | 20 | 0.6 |

| JX5017 | 5.0 | 1.7 | 4.0 | 20 | 17.1 | 0.5 |

| JX5022 | 5.0 | 2.2 | 4.3 | 30 | 15 | 0.5 |

| JX5025 | 5.0 | 2.5 | 3.4 | 25 | 45 | 0.5 |

| JX5115 | 5.1 | 1.5 | 3.7 | 28 | 0.5×45° | 0.2 |

| JX5116 | 5.1 | 1.6 | 2.5 | 30 | 22 | 0.2 |

| JX5216 | 5.2 | 1.6 | 3.8 | 25 | 20 | 0.5 |

| JX5218 | 5.2 | 1.8 | 4.0 | 18 | 40 | 0.5 |

| JX5220 | 5.2 | 2.0 | 3.5 | 30 | 15 | 0.5 |

| JX5315 | 5.3 | 1.5 | 3.8 | 20 | 20 | 0.5 |

| JX53155 | 5.3 | 1.55 | 4.3 | 28 | 15 | 0.5 |

| JX5315A | 5.3 | 1.5 | 4.0 | 30 | 20 | 0.5 |

| ... | … | … | … | … | … | … |

Packing details

Shipping ways

Production process