- Overview

- Product Description

- Technical Parameter

- Product Application

- About Us

- FAQ

Basic Info.

Packaging & Delivery

Product Description

The linear vibratory screen uses vibration motor as vibration source, the sieved materials are jumped and moved in the straight movement at the same time. The materials are uniformly entered into entrance, then they go through the screen to separate the materials with different sizes, which was discharged from different gates. It is suitable for low consuming, high output and simple structure, easily maintain all-closed structure, no powder dispersed, automatic discharge.

Features of linear vibratory screen

| Can reach a maximum six-layer screen machine |

| Used for the coarse screening with large production output |

| Voltage as request of your local market |

| Accord with ISO9001:2008 and CE, BV, GSG |

Technical parameter

| Model | Material granularity (mm) | Angle | Amplitude | Layer | Power (KW) | Dimension (mm) |

| ZX520 | 0.074-10 | 1-7 degree | 3-4.5mm | 1-6 | 2*(0.37-0.75) | 500*2000 |

| ZX525 | 2*(0.37-0.75) | 500*2500 | ||||

| ZX1020 | 2*(0.55-1.10) | 1000*2000 | ||||

| ZX1025 | 2*(0.55-1.10) | 1000*2500 |

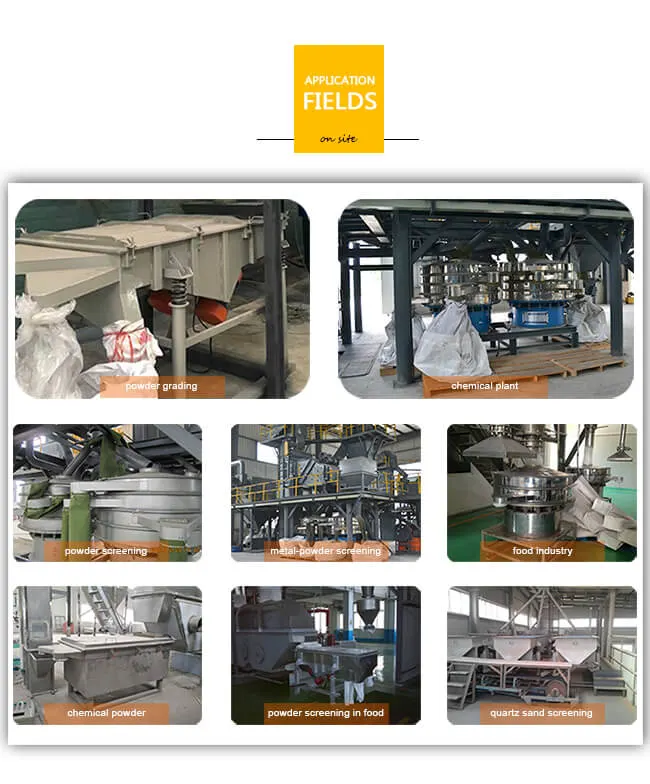

Applicable industries

1. Chemical industry: resin pigment, medicine, grease, fire-extinguishing agent, rubber and plastic.2. Grinding material, glass, ceramic industry: silica sand, alumina, grinding material, glass powder, refractory material.

3. Food industry: sugar, salt, alkali, gourmet powder, starch, milk powder, bean milk, yeasts must, pollen, food additive.

4. Paper-making industry: whitish soil slush, black and white fluid, filling fluid, waste fluid and paper-making fluid.

5. Mine industry: quartz sand, ore, titanium oxide, zinc oxide.

6. Mechanical industry: casting sand, powder metallurgy, electromagnetic material and metal powder.

7. Others: carbon black, light calcium, additive, pearl powder, catalyst

Matters needing attention

1. Once the machine on operation, the vibration part shall not be connected or contact with any object.

2. When feeding materials, pay attention to ensure the uniform feeding.

3. When the material through down, keeping no big impact to damage the screen.

4. Before operation and power off, there should no be any material on screen surface.

5. If there is any abnormal sound in the operation, the machine should be shutdown immediately and to check.

6. Ensure vibration motor maintenance regularly.

How to get one set of linear vibratory screen? Only by telling us the following information for selection:

1. Material

| Name of material |

| Characteristic of material, such as water content, size of material, specific gravity |

| Capacity per hour you asked |

| How many layers you asked |

| Sieve mesh for each layer |

| Voltage, Hertz, Phase |

Q1. Are you a trading company or factory?

A: We are factory and we have experienced technicians(more than 20 years experience in screening and conveying flied).

Q2: How does your after-sale service work if the product got damaged?

A: In the guarantee time of 12 months, our general after-sale service will change the damaged parts for the customer, but if the damage could be repaired by slight cost, we would wait for the customer's bill for the fix cost and refund this part of cost.(note: Vulnerable parts do not include.)

Q3: How do you make our business long-term and good relationship?

A: We keep good quality and competitive price to ensure our customers benefit .

We are factory and be able to give you the best price with good quality, and we have a policy that " for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity"

Q4: Does HENGYU has oversea selling company or branch office?

A:So far, we only have some oversea business partners. If you would like to resell our products with your own brand, we'd like to provide our best support for you to do local market. Do contact us without hesitate.