Basic Info.

Product Description

Definition of composite roll

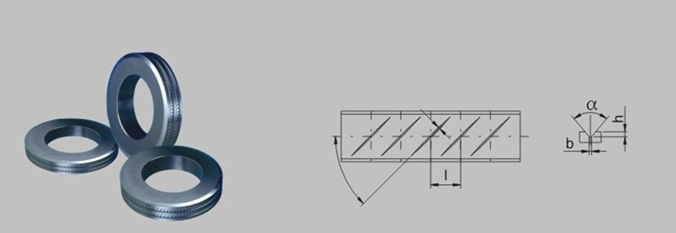

Cemented carbide roll ring is a kind of tool material which consists of tungsten carbide and cobalt with high hardness and wear resistance.

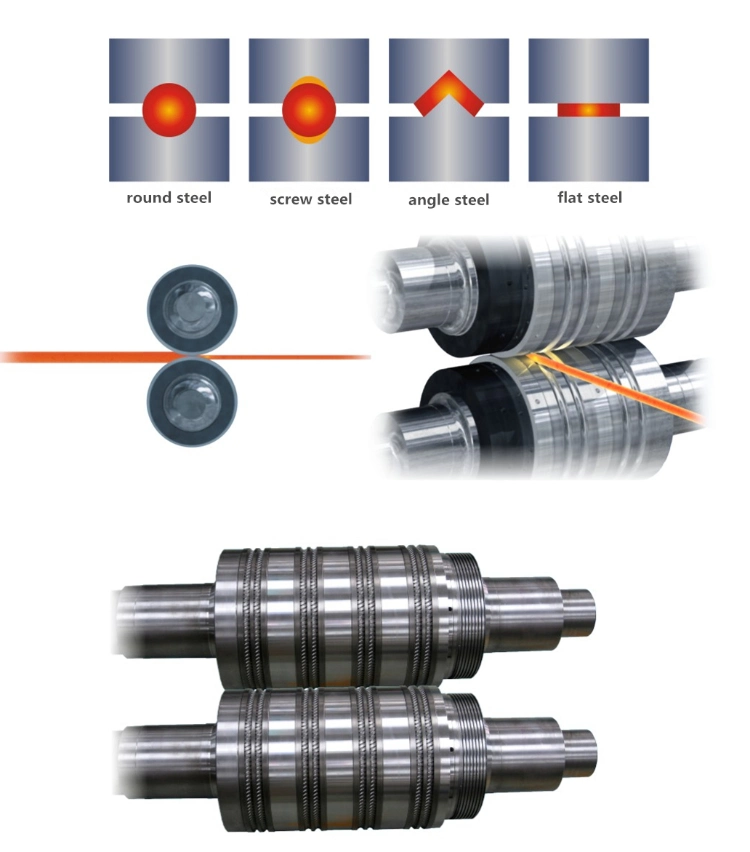

The composite roll is that cemented carbide roll rings and steel shaft are compounded into a whole through the special method, which is used for rolling round steel, screw steel, square steel,, flat steel and angle steel,etc.

Suitable rolling speed of composite roll

2-50m/s

Advantage of composite roll

- 1.The quality of steel products can be promoted. The surface quality and tolerance of products can be thoroughly improved. The negative deviation can be controlled more precisely.

- 2.The change frequency of groove and roll can be reduced. The downtime can be shortened. The labor intensity can be reduced in rolling workshop, increasing productivity and output can create greater economic benefit at the same time

- 3.The rejection rate of products can be reduced

- 4.Greatly reducing the steel cost per ton is an effective way for enterprise to reduce cost and increase benefit

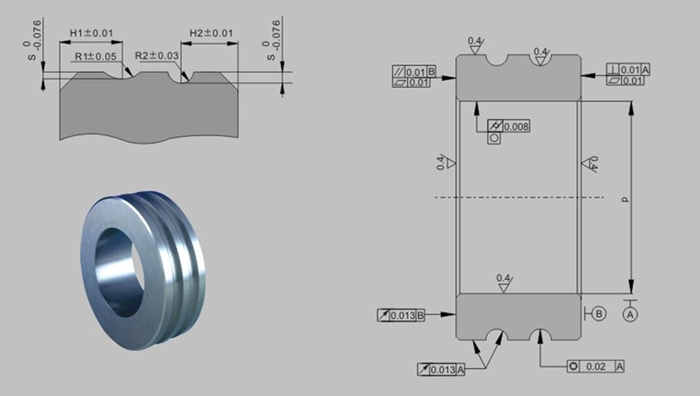

Dimensions and Precision

Rang of O.D. (D/mm) | Rang of I.D. (d/mm) | Rang of height (H/mm) |

145 ~380 | 87 ~ 260 | 62 ~ 130 |

Note: We can supply them according to the drawings provide by customers.

Tolerances allowable for the O.D. , I.D. and height of roll rings

Precision class | Grade 1 | Grade 2 | Grade 3 | Grade 4 | Unit:mm |

O.D. (+/-) | 0.02 | 0.05 | 0.10 | 0.15 | Special requirements |

I.D. (+/-) | IT5 | IT6 | IT7 | IT8 | |

Height (-) | 0.03 | 0.1 | 0.2 | 0.5 |

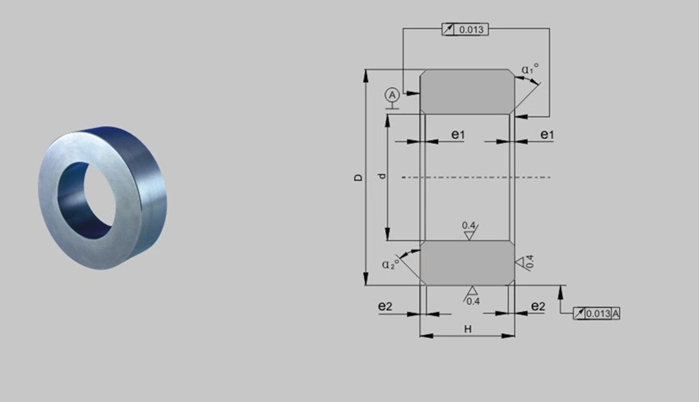

Technical requirements for groove roller ring

Roll rings for high speed rolling of ribbed steel bars

The allowable deviation of carbide roll rings

Radial runout of groove ≤0.013mm

Radial runout of periphery ≤0.013mm

End face runout ≤0.02mm

End face planeness≤0.01mm

End face of parallelism ≤0.01mm

Inner hole cylindericity ≤0.01mm

Roughness of carbide rolls

Inner hole roughness 0.4 μm

Periphness roughness 0.4 μm

End face roughness 0.4 μm

The allowable deviation in external diameter, internal diameter and height is to be based on customers' needs.

The Construction of cemented carbide composite roll

Application

If there is any questions or demands, please feel free to contact us.

Company Introduction

About Lihua Cemented Carbide Factory

Established in 1996, specialized in production carbide products more than 20 years and located in Zhuzhou city which is the hometown of tungsten carbide in China.

Our products sold well to worldwide, has been build a long term relationship with our customers from Italy, Portugal, German, Turkey, USA, Mexico, India, Australia, South Africa etc.

Main Products

Our Main products include : Carbide Screwed Boring Bar, Plates, Rods, Sticks, Bushings, TP nozzles, 3D Printer Nozzles, Saw Blades, End Mills & Drill Bits, CNC inserts, Value Seats, Rotary Burrs, wheel cutters, Grits, Customized cutter woodworking tool, V-cutter, Shoes cutter ects. Any kinds of customized carbide products can be made.

Monthly Capacity of 15 Tons

We have sophisticated equipments, such as Sintering Furnace, Automatic suppress Machine, Manual Hydraulic Suppress Machine, Ball Mill Machine, Drying Machine, Mixing Machine ect, Our production capacity has up to 15 Tons per month. Customized is welcome, customized sample can be ready in 3-5 days and 1 day can deliver for stocks.

Strictly QC

We have a professional QC team follow to the System of ISO9001:2008, Covering the Raw Materials Incoming, Production Processes, Finished Products and Packaging to ensure high quality products output.

Shipping

Foreign Sales Manager : Coco Su

Factory Add: Building B-11,E-commerce Industrial Park ,Xinma South Road ,Tianyuan Zone ,Zhuzhou City ,Hunan Provice ,China 412000