Basic Info.

Origin

China

HS Code

8209001000

Production Capacity

30000PCS/Month

Product Description

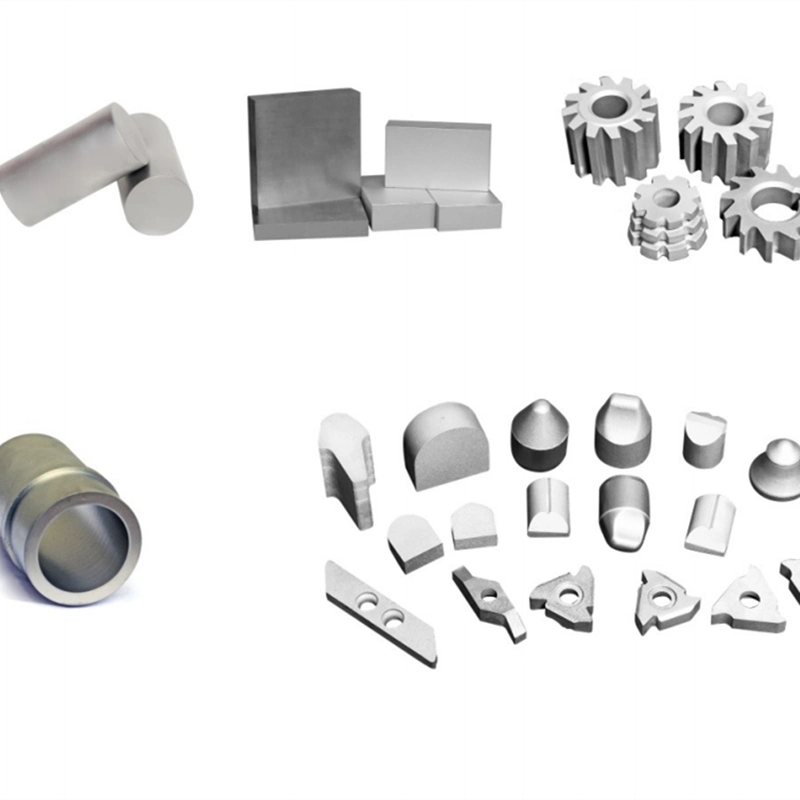

China Manufacturer ZGCC Yg8 Tungsten Carbide

1. Main products are Cold Heading Die, Powder Metallurgy die, Non-standard Special-shaped wear-resistant Punching tools,etc.

2. We brings together an excellent technical team and uses advanced and mature production technology and adopts advanced prodluction facilities and analysis equipments.

3. Based on the tenet of "Quality First, Customer First", relying on continuous technological innovation.

Wear resistance and good toughness

| Grade | WC particle Size | Cobalt content | Density | Hardness | Bonding strength | Impact strength | Application |

| XR | um | Co% | g/cm3 | HRA | kgf/mm2 | kgf-m/cm2 | Wire drawing die, pipe drawing die, powder metallurgy die, die resistant die, etc. |

| XR06 | <0. 6 | 6 | 14. 70 | 94. 5 | 360 | 0. 20 | |

| XR1 | 1-2 | 5. 5 | 14. 85 | 92. 0 | 300 | 0. 30 | |

| XR2 | 1-3 | 6. 5 | 14. 85 | 91. 0 | 320 | 0. 40 | |

| XR3 | 2-3 | 9 | 14. 60 | 89. 0 | 320 | 0. 55 | |

| XR5 | 2-3 | 12 | 14. 30 | 88. 0 | 330 | 0. 65 | Wear-resistant and impact-resistant molds, screw molds, strong beam molds, cold extrusion molds, powder metallurgy molds |

| XR6 | 2-3 | 14 | 14. 10 | 87. 0 | 320 | 0. 75 |

High strength and toughness

| Grade | WC particle Size | Cobalt content | Density | Hardness | Bonding strength | Impact strength | Application |

| XT | um | Co% | g/cm3 | HRA | kgf/mm2 | kgf-m/cm2 | |

| XT6 | 3-6 | 15 | 13. 80 | 86. 0 | 300 | 0. 80 | Stainless steel spider silk die, cold extrusion die |

| XT1 | 3-6 | 20 | 13. 38 | 84. 8 | 280 | 0. 89 | Nut die, screw die, six-piece cold extrusion die, stainless steel screw and bolt, ordinary screw die, carbon steel |

| XT7 | 2-6 | 20 | 13. 40 | 85. 3 | 290 | 0. 88 | |

| XR65 | 2-6 | 18 | 13. 70 | 85. 0 | 300 | 0. 78 | |

| XR70 | 3-6 | 15 | 14. 00 | 85. 0 | 280 | 0. 75 | Impact-resistant forging die, screw die |

| XR80 | 3-6 | 20 | 13. 50 | 84. 0 | 280 | 0. 85 | Screw mold, nut mold, six-piece mold |

| XR90 | 6-9 | 22 | 13. 35 | 82. 5 | 250 | 0. 95 | Screw die, nut die, thread trimmer die |

| XR95 | 6-9 | 25 | 13. 10 | 81. 5 | 240 | 1.00 | High Impact Forging Dies, Nut Dies, Flange Nut Dies |

High Strength high toughness

| Grade | WC particle Size | Cobalt content | Density | Hardness | Bonding strength | Impact strength | Application |

| XRT | um | Co% | g/cm3 | HRA | kgf/mm2 | kgf-m/cm2 | |

| XRT98 | 6-9 | 25 | 13. 00 | 83. 0 | 250 | 1.00 | |

| XRT100 | 2-3 | 22 | 13. 25 | 83.0 | 270 | 0. 98 | Countersunk head bolts, drywall screws, self-tapping screws, flower tooth dies |

| XRT105 | 3-6 | 23 | 13. 10 | 83. 5 | 270 | 1.00 | Impact resistance, corrosion resistance, good toughness, nut die, warm forging die, stainless steel |

| XRT106 | 1-3 | 25 | 12.90 | 85. 0 | 310 | 1.05 | Countersunk head bolts, drywall screws, self-tapping screws, flower tooth dies |

| XRT110 | 2-3 | 25 | 12.95 | 84. 0 | 300 | 1.05 | Impact resistance and wear resistance, screw die, forming die, drawing die |

| XRT115 | 1-2 | 25 | 12.90 | 85. 0 | 310 | 1.05 | Impact resistance and wear resistance, screw die, forming die, drawing die |

| XRT120 | 1-2 | 22.5 | 13. 20 | 86.0 | 310 | 0. 98 | Wear-resistant and good toughness, strong beam die, stamping die, stainless steel |

| XRT150 | 0.8-1 | 15 | 13. 90 | 89.0 | 2370 | 0.75 | Wear resistance, screw die, stamping die, powder forming die, progressive die |

| Grade | WC particle Size | Cobalt content | Density | Hardness | Bonding strength | Impact strength | Application |

| NR | um | Co% | g/cm3 | HRA | kgf/mm2 | kgf-m/cm2 | |

| NR9 | 1. 0 | Ni | 14. 5 | 90 | 290 | 0. 45 | For magnetic materials, powder metallurgy forming molds |

| NR18 | 3. 0-6. 0 | Ni | 13. 5 | 83 | 240 | 0. 65 |

| Grade | WC particle Size | Cobalt content | Density | Hardness | Bonding strength | Impact strength | Application |

| XF | um | Co% | g/cm3 | HRA | kgf/mm2 | kgf-m/cm2 | |

| XF12 | 0.8-2.0 | 12 | 14. 15 | 90 | 360 | 0. 65 | Stamping dies, progressive die forming dies, drawing dies, powder metallurgy middle dies, punches, punches, mandrels |

| XF13 | 0.8 | 13 | 14. 05 | 91 | 370 | 0. 70 | |

| XF14 | 0.8 | 14 | 13.95 | 90 | 380 | 0.75 |

DHL: 5-7 working days;

UPS: 7-9 working days;

FedEx: 7-9 working days;

EMS: 25-30 working days;

China Post: Depends on ship to which country;

Sea: Depends on ship to which country

Q1: Are you trading company or manufacturer ?

Q1: Are you trading company or manufacturer ?A: We are manufacturer and do both OEM and ODM. We have our own R&D team.

Q2: How to order?

A: Send inquiries → Reply you quotations → Discuss details → Confirm samples →

Deposit → Mass production → Cargo ready → Balance/Delivery → More cooperations.

Q3: What is your payment method ?

A: We accept T/T, Western Union, Paypal and MoneyGram, those depend on specific cases.

Q4: How long is your delivery time?

A: Usually 1-3 working days for products in stock. If we do special offer, it usually takes

4-6 weeks. Also delivery time is according to your quantity of order.

Q5: How to transport?

A: DHL, UPS, FedEx, TNT, EMS, China Post and Sea are available.Also other shipping ways are

available. Please feel free to contact us for other shipping ways.

Q6: How is your warranty service?

A: We do strict test before shipping and guarantee for 365 days. If quality problem you

could send us pictures or video clips about problem. Then we deal with the problem ASAP.

China Manufacturer ZGCC Yg8 Tungsten Carbide