Basic Info.

Transport Package

in Plastic Box

Specification

330mm, 310mm, 100mm...customized

Trademark

Grand Sea

Origin

China

HS Code

8209002900

Production Capacity

1000t/Year

Product Description

High Quality Super Hard Solid Tungsten Carbide Rod

Grand Sea Cemented Carbide made tungsten carbide rod which is hard and tough, is the raw material of producing the alloy cutting tools such as end milling cutter, drill and reamer. These cutting tools are widely used for metal processing..

We have developped Ultrafine grade Carbide Rods for Super Hard Cutting Tools, such as our grade H09U, H06U-T.

Grand Sea Cemented Carbide Rods have good reputation in USA, EU, Japenese and Korea makert.

Grand Sea Cemented Carbide Rods include

1. Tungsten Carbide long Rod unground and grouned h5/h6

2. Tungsten Carbide short Rod in h4/h5/h6/h7

3. Tungsten Carbide rod in Inch size in h4/h5/h6/h7

4. Tungsten Carbide PCB rod

Grand Sea Grade Recommandation

Application

We Produce:

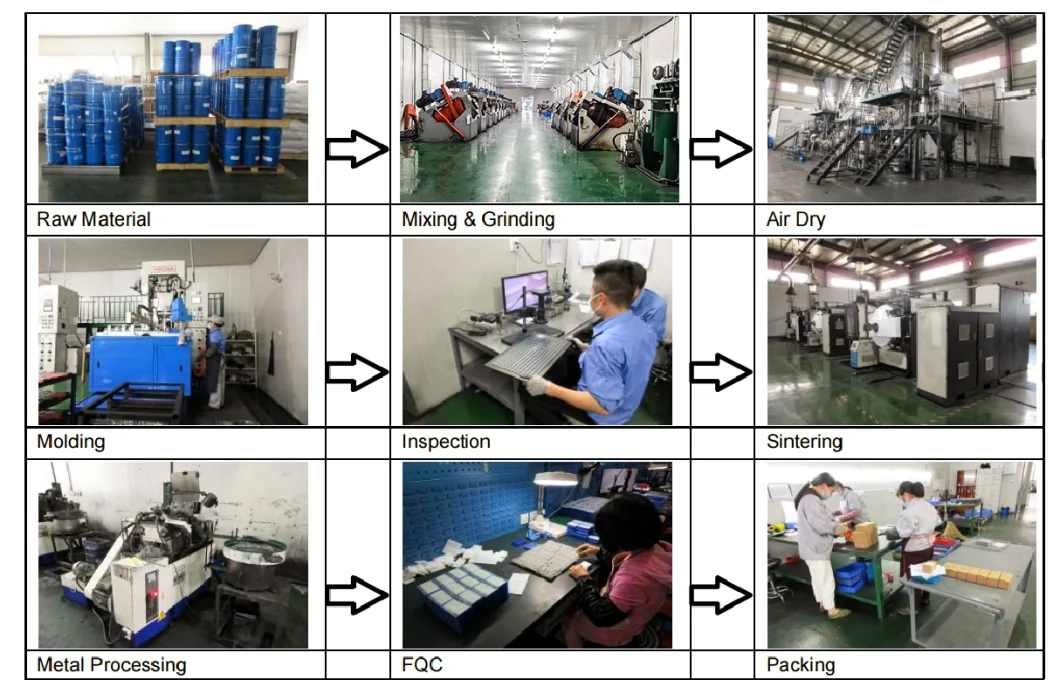

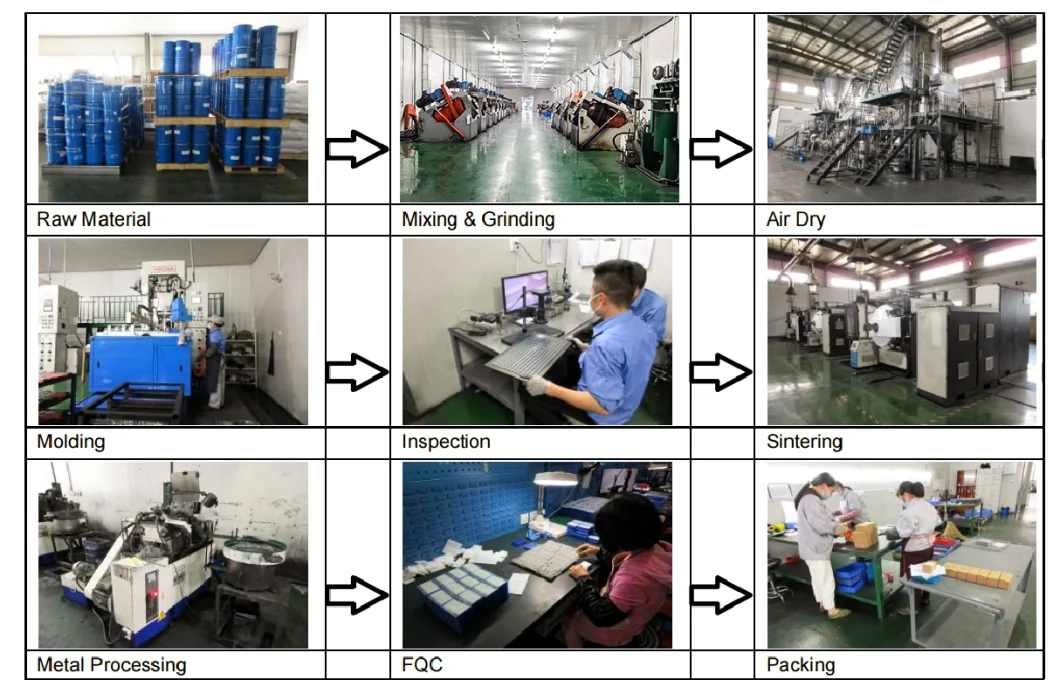

Production Workflow Chart

Grand Sea Cemented Carbide made tungsten carbide rod which is hard and tough, is the raw material of producing the alloy cutting tools such as end milling cutter, drill and reamer. These cutting tools are widely used for metal processing..

We have developped Ultrafine grade Carbide Rods for Super Hard Cutting Tools, such as our grade H09U, H06U-T.

Grand Sea Cemented Carbide Rods have good reputation in USA, EU, Japenese and Korea makert.

Grand Sea Cemented Carbide Rods include

1. Tungsten Carbide long Rod unground and grouned h5/h6

2. Tungsten Carbide short Rod in h4/h5/h6/h7

3. Tungsten Carbide rod in Inch size in h4/h5/h6/h7

4. Tungsten Carbide PCB rod

Grand Sea Grade Recommandation

| Grade | WC % | CO % | Grain size (um) | Density (g/cm³)±0.1 | Hardness (HRA)±0.5 | TRS (kgf/mm²) |

| H09U | 91 | 9 | 0.3 | 14.5 | 93.7 | >350 |

| H12U-T | 88 | 12 | 0.3 | 14.2 | 93 | >350 |

| H06U-T | 94 | 6 | 0.4 | 14.9 | 94.5 | >380 |

| H08U-K | 92 | 8 | 0.4 | 14.7 | 93.2 | >380 |

| H12U | 88 | 12 | 0.4 | 14.3 | 92.5 | >350 |

| H10S | 90 | 10 | 0.6 | 14.4 | 92.1 | >350 |

| H10F | 90 | 10 | 0.8 | 14.4 | 91.8 | >350 |

| S1 | 88 | 12 | 0.6 | 14.2 | 11.2 | >380 |

Application

We Produce:

Production Workflow Chart