- Overview

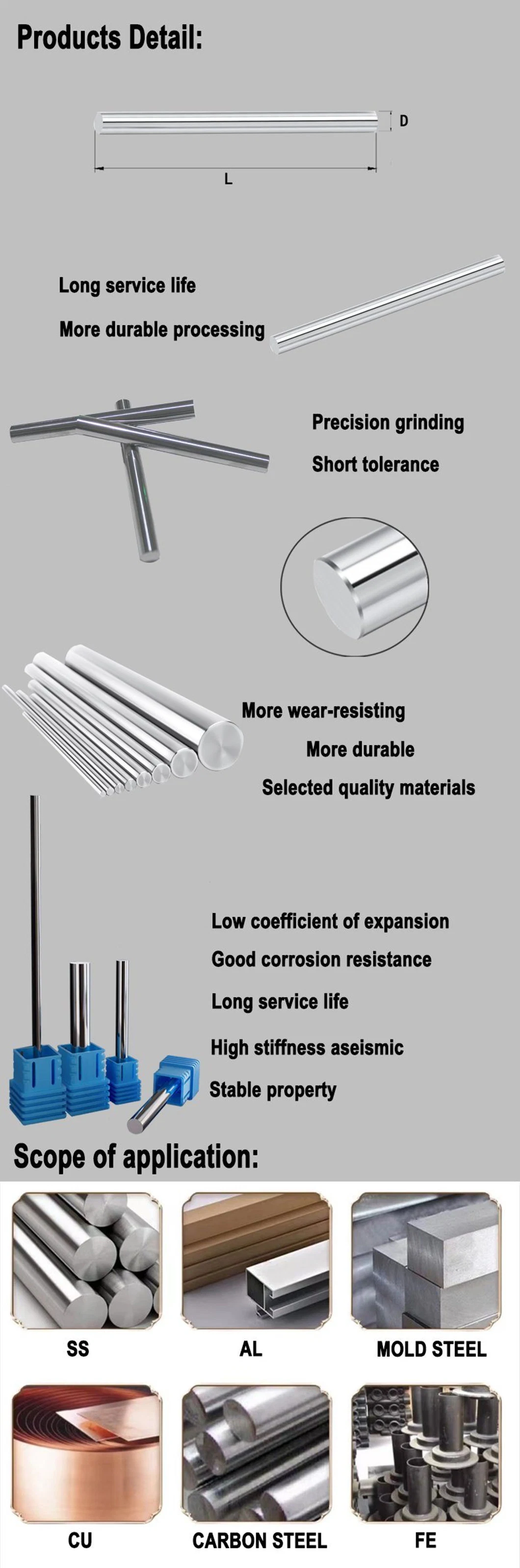

- Our Advantages

- Product Description

- Product display

- Product details

- Corporate presence

- Qualification certification

- FAQ

Basic Info.

Packaging & Delivery

Product Description

- We has a set of standardized process control measures and control point,and can provide users with high-quality production that meets the requirements in an all-round way.

- Can be customized with various models you need.

- With qualification certificates and a number of patents, we have a large production capacity.

| 1.Product Name:Tungsten Steel Round Bar | |

| 2.function: Making the tools needed for CNC machine tools | |

| 3.Advantages: Sharp and durable,Smooth chip removal | |

| Material: | Tungsten Carbide,Solid Carbide,Cemented Carbide |

| Product Type: | Tungsten Steel Round Bar |

| Coating: | nano-coating |

| Size: | Standard size or as your request |

| Suitable For: | Various PCB cutting tools |

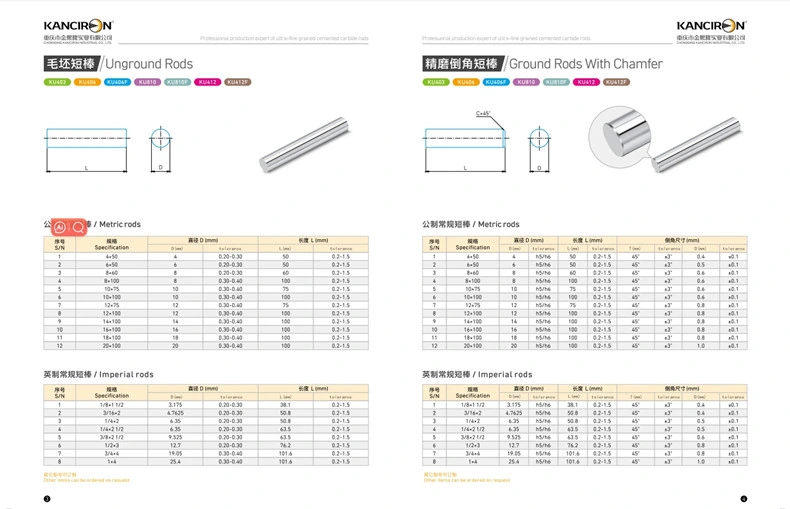

| Unground Rods Metric rods | |||||

| serial number S/N | Specification | Diameter D(mm) | Length L(mm) | ||

Diameter | Tolerance | Length | Tolerance | ||

| 1 | 4×50 | 4 | 0.20-0.30 | 50 | 0.2-1.5 |

| 2 | 6×50 | 6 | 0.20-0.30 | 50 | 0.2-1.5 |

| 3 | 8×60 | 8 | 0.20-0.30 | 60 | 0.2-1.5 |

| 4 | 8×100 | 8 | 0.30-0.40 | 100 | 0.2-1.5 |

| 5 | 10×75 | 10 | 0.30-0.40 | 75 | 0.2-1.5 |

| 6 | 10×100 | 10 | 0.30-0.40 | 100 | 0.2-1.5 |

| 7 | 12×75 | 12 | 0.30-0.40 | 75 | 0.2-1.5 |

| 8 | 12×100 | 12 | 0.30-0.40 | 100 | 0.2-1.5 |

| 9 | 14×100 | 14 | 0.30-0.40 | 100 | 0.2-1.5 |

| 10 | 16×100 | 16 | 0.30-0.40 | 100 | 0.2-1.5 |

| 11 | 18×100 | 18 | 0.30-0.40 | 100 | 0.2-1.5 |

| 12 | 20×100 | 20 | 0.30-0.40 | 100 | 0.2-1.5 |

| Unground Rods Imperial rods | |||||

| serial number S/N | Specification | Diameter D(mm) | Length L(mm) | ||

Diameter | Tolerance | Length | Tolerance | ||

| 1 | 1/8×1 1/2 | 3.175 | 0.20-0.30 | 38.1 | 0.2-1.5 |

| 2 | 3/16×2 | 4.7625 | 0.20-0.30 | 50.8 | 0.2-1.5 |

| 3 | 1/4×2 | 6.35 | 0.20-0.30 | 50.8 | 0.2-1.5 |

| 4 | 1/4×2 1/2 | 6.35 | 0.20-0.30 | 63.5 | 0.2-1.5 |

| 5 | 3/8×2 1/2 | 9.525 | 0.20-0.30 | 63.5 | 0.2-1.5 |

| 6 | 1/2×3 | 12.7 | 0.20-0.30 | 76.3 | 0.2-1.5 |

| 7 | 3/4×4 | 19.05 | 0.30-0.40 | 101.6 | 0.2-1.5 |

| 8 | 1×4 | 25.4 | 0.30-0.40 | 101.6 | 0.2-1.5 |

| Ground rods with chamfer Metric rods | |||||||||

| serial number S/N | Specification | Diameter D(mm) | Length L(mm) | chamfer dimension | |||||

| Diameter | Tolerance | Length | Tolerance | chamfering angle | Tolerance | Chamfering length | Tolerance | ||

| 1 | 4×50 | 4 | h5/h6 | 50 | 0.2-1.5 | 45° | ±3° | 0.4 | ±0.1 |

| 2 | 6×50 | 6 | h5/h6 | 50 | 0.2-1.5 | 45° | ±3° | 0.5 | ±0.1 |

| 3 | 8×60 | 8 | h5/h6 | 60 | 0.2-1.5 | 45° | ±3° | 0.6 | ±0.1 |

| 4 | 8×100 | 8 | h5/h6 | 100 | 0.2-1.5 | 45° | ±3° | 0.6 | ±0.1 |

| 5 | 10×75 | 10 | h5/h6 | 75 | 0.2-1.5 | 45° | ±3° | 0.6 | ±0.1 |

| 6 | 10×100 | 10 | h5/h6 | 100 | 0.2-1.5 | 45° | ±3° | 0.6 | ±0.1 |

| 7 | 12×75 | 12 | h5/h6 | 75 | 0.2-1.5 | 45° | ±3° | 0.8 | ±0.1 |

| 8 | 12×100 | 12 | h5/h6 | 100 | 0.2-1.5 | 45° | ±3° | 0.8 | ±0.1 |

| 9 | 14×100 | 14 | h5/h6 | 100 | 0.2-1.5 | 45° | ±3° | 0.8 | ±0.1 |

| 10 | 16×100 | 16 | h5/h6 | 100 | 0.2-1.5 | 45° | ±3° | 0.8 | ±0.1 |

| 11 | 18×100 | 18 | h5/h6 | 100 | 0.2-1.5 | 45° | ±3° | 0.8 | ±0.1 |

| 12 | 20×100 | 20 | h5/h6 | 100 | 0.2-1.5 | 45° | ±3° | 1.0 | ±0.1 |

| Ground rods with chamfer Imperial rods | |||||||||

| serial number S/N | Specification | Diameter D(mm) | Length L(mm) | chamfer dimension | |||||

| Diameter | Tolerance | Length | Tolerance | chamfering angle | Tolerance | Chamfering length | Tolerance | ||

| 1 | 1/8×1 1/2 | 3.175 | 0.20-0.30 | 38.1 | 0.2-1.5 | 45° | ±3° | 0.4 | ±0.1 |

| 2 | 3/16×2 | 4.7625 | 0.20-0.30 | 50.8 | 0.2-1.5 | 45° | ±3° | 0.5 | ±0.1 |

| 3 | 1/4×2 | 6.35 | 0.20-0.30 | 50.8 | 0.2-1.5 | 45° | ±3° | 0.6 | ±0.1 |

| 4 | 1/4×2 1/2 | 6.35 | 0.20-0.30 | 63.5 | 0.2-1.5 | 45° | ±3° | 0.6 | ±0.1 |

| 5 | 3/8×2 1/2 | 9.525 | 0.20-0.30 | 63.5 | 0.2-1.5 | 45° | ±3° | 0.6 | ±0.1 |

| 6 | 1/2×3 | 12.7 | 0.20-0.30 | 76.3 | 0.2-1.5 | 45° | ±3° | 0.6 | ±0.1 |

| 7 | 3/4×4 | 19.05 | 0.30-0.40 | 101.6 | 0.2-1.5 | 45° | ±3° | 0.8 | ±0.1 |

| 8 | 1×4 | 25.4 | 0.30-0.40 | 101.6 | 0.2-1.5 | 45° | ±3° | 0.8 | ±0.1 |

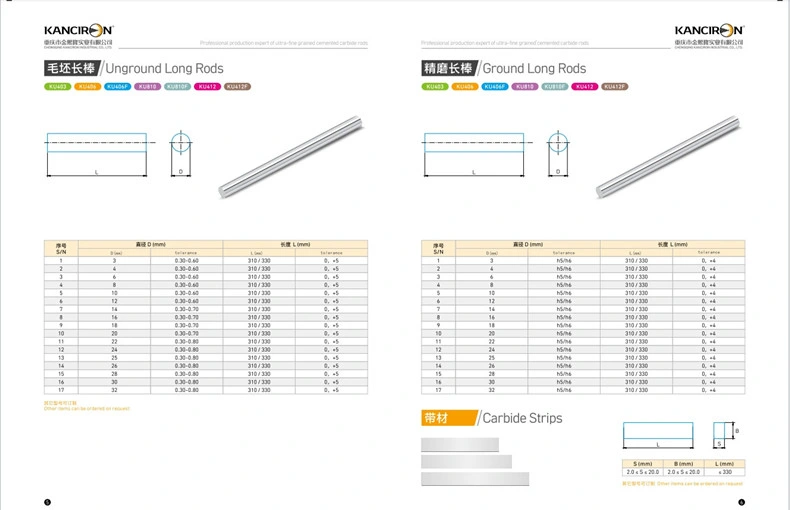

| Unground Long Rods Imperial rods | ||||

| serial number S/N | Diameter D(mm) | Length L(mm) | ||

Diameter | Tolerance | Length | Tolerance | |

| 1 | 3 | 0.30-0.60 | 310/330 | 0,+5 |

| 2 | 4 | 0.30-0.60 | 310/330 | 0,+5 |

| 3 | 6 | 0.30-0.60 | 310/330 | 0,+5 |

| 4 | 8 | 0.30-0.60 | 310/330 | 0,+5 |

| 5 | 10 | 0.30-0.60 | 310/330 | 0,+5 |

| 6 | 12 | 0.30-0.60 | 310/330 | 0,+5 |

| 7 | 14 | 0.30-0.70 | 310/330 | 0,+5 |

| 8 | 16 | 0.30-0.70 | 310/330 | 0,+5 |

| 9 | 18 | 0.30-0.70 | 310/330 | 0,+5 |

| 10 | 20 | 0.30-0.70 | 310/330 | 0,+5 |

| 11 | 22 | 0.30-0.80 | 310/330 | 0,+5 |

| 12 | 24 | 0.30-0.80 | 310/330 | 0,+5 |

| 13 | 25 | 0.30-0.80 | 310/330 | 0,+5 |

| 14 | 26 | 0.30-0.80 | 310/330 | 0,+5 |

| 15 | 28 | 0.30-0.80 | 310/330 | 0,+5 |

| 16 | 30 | 0.30-0.80 | 310/330 | 0,+5 |

| 17 | 32 | 0.30-0.80 | 310/330 | 0,+5 |

| Ground Long Rods Imperial rods | ||||

| serial number S/N | Diameter D(mm) | Length L(mm) | ||

Diameter | Tolerance | Length | Tolerance | |

| 1 | 3 | h5/h6 | 310/330 | 0,+4 |

| 2 | 4 | h5/h6 | 310/330 | 0,+4 |

| 3 | 6 | h5/h6 | 310/330 | 0,+4 |

| 4 | 8 | h5/h6 | 310/330 | 0,+4 |

| 5 | 10 | h5/h6 | 310/330 | 0,+4 |

| 6 | 12 | h5/h6 | 310/330 | 0,+4 |

| 7 | 14 | h5/h6 | 310/330 | 0,+4 |

| 8 | 16 | h5/h6 | 310/330 | 0,+4 |

| 9 | 18 | h5/h6 | 310/330 | 0,+4 |

| 10 | 20 | h5/h6 | 310/330 | 0,+4 |

| 11 | 22 | h5/h6 | 310/330 | 0,+4 |

| 12 | 24 | h5/h6 | 310/330 | 0,+4 |

| 13 | 25 | h5/h6 | 310/330 | 0,+4 |

| 14 | 26 | h5/h6 | 310/330 | 0,+4 |

| 15 | 28 | h5/h6 | 310/330 | 0,+4 |

| 16 | 30 | h5/h6 | 310/330 | 0,+4 |

| 17 | 32 | h5/h6 | 310/330 | 0,+4 |

The company is committed to the R&D,production and sales of ultra-fine tungsten carbide powder,ultra-grain cemented carbide bars and other related products.The company has always adhered to the business philosophy of "quality first,intergrity-based,innovation and farsightedness",and has become a well-known cemented carbide bar supplier in China.

The cemented carbide bars produced by Kanciron Industry have excellent performance and are mainly used for cutting,drilling and milling of metal materials,composite materials,superalloys and other materials.The products are widely used in metallurgy,machinery,automobile,electronics,medical and other related fields.In recent years,through continuous R&D and innovation,the company has developed a number of series of brands suitable for processing high hardness materials,which are widely welcomed by customers.

Q1.How is Quality Ensured?

All our processes strictly adhere to IS09001-2015 quality system. We have strict quality control from producing to delivery. Our company has strong technical support. We have cultivated a group of managers who are familiar with product quality, and good at modern concept of management.

Q2.How to Custom-made (OEM/ODM)?

If you have a new product drawing or a sample, please send to us. We can custom-made the hardware as you required. We will also provide our professional advice of the products to make the design to be more realistic and maximize the performance.

Q3.Can You Strictly Follow The Tolerance on the Drawing and Meet the High Precision?

Yes. We can provide high precision parts and make the parts as your drawing.

Q4. How Long does the Whole Procedure being Worked Out?

After you place an order, the production handling time is about 30 days. We need 15 days to prepare all the stuff then 15 days for manufacturing.

Q5.What's Your Delivery Time?

Standard parts: 7-15days

Non-standard parts: 15-25days

Q6. Is Free Shipping Possible?

We don't offer a free shipping service. We can have a discount if you buy a large quantity of products.