Basic Info.

Product Description

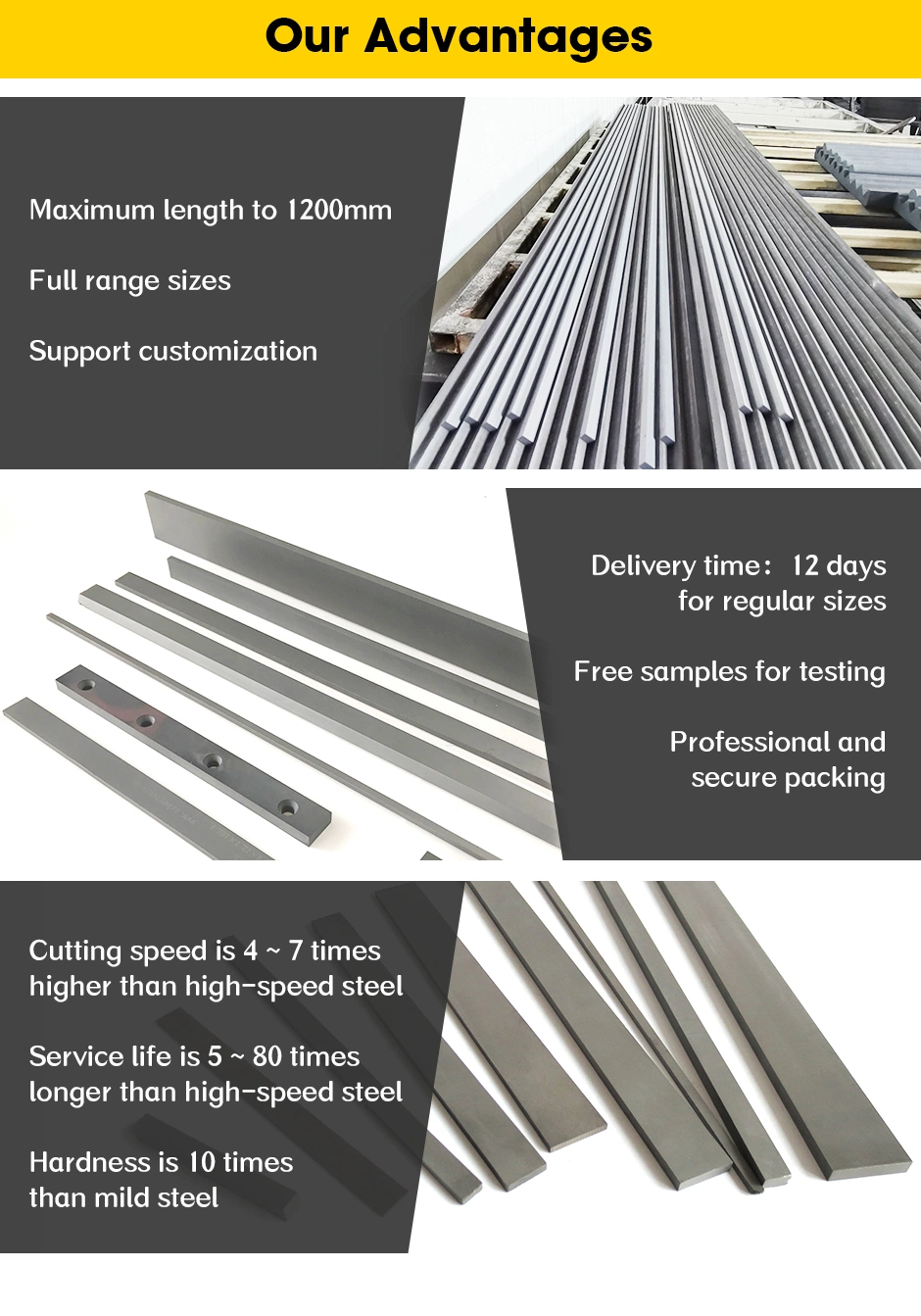

High-quality tungsten carbide flat strips

Tungsten carbide strip has high hardness and high wear resistance, it is an ideal choice to use in cutting kinds of wood.

With high-quality raw material and advanced equipment, Zzbetter provides customers with superior quality carbide strips.

- Easy to be brazed, has good wear resistance and toughness.

- Ultrafine grain size raw material to keep excellent strength and hardness.

- Both standard sizes and customized sizes are available.

Grade Recommended:

| ZZBT Grade | ISO Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPα) | Grain Size | Performance & Application Recommended |

| UBT910 | K20 | 14.6-15.0 | 90~90.5 | 2200~2400 | Medium | High hardness, suitable for roughing of iron, solid wood, dry wood or nonferrous metal, ceramic and other alloys. |

| UBT40S | K25 | 14.6-15.0 | 90~90.5 | 2600~2800 | Fine | High toughness, easy to be brazed without heat preservation. Suitable for rosewood, solid wood, pinewood, and other wood with a lot of stammers. |

| UBT920 | K10~K15 | 14.6-15.0 | 91~91.8 | 2400~2600 | Fine | Good versatility, suitable for kinds of solid wood, rosewood, and MDF. |

| UBT15T | K10~K15 | 14.6-15.0 | 92.5~93 | 2000~2200 | Ultrafine | High hardness, suitable for finishing of iron, nonferrous metal, ceramic and other alloying, semi-finishing of hardwood, chipboard, MDF and HDF. Heat preservation is necessary when brazing. |

| UBT10T | K10 | 14.6-15.0 | 92.5~93 | 1800-2000 | Ultrafine | High hardness, suitable for finishing of iron, nonferrous metal, ceramic and other alloying, semi-finishing of hardwood, chipboard, MDF and HDF. Better to use silver soldering. |

| UBT10C | K40 | 13.8-14.2 | 87.5~88 | 2800~3000 | Coarse | High toughness, difficult to break a tooth. Specially used for finger jointing tool. |

Types and Sizes

| Type | T*W*L (mm) | T (mm) | W (mm) | L (mm) |

| FS05 | T x 5 x 320 | 2.0~15.0 | 5 | 320 |

| FS06 | T x 6 x 320 | 2.0~15.0 | 6 | 320 |

| FS07 | T x 7 x 320 | 2.0~15.0 | 7 | 320 |

| FS08 | T x 8 x 320 | 2.0~15.0 | 8 | 320 |

| FS09 | T x 9 x 320 | 2.0~15.0 | 9 | 320 |

| FS10 | T x 10 x 320 | 2.0~15.0 | 10 | 320 |

| FS11 | T x 11 x 320 | 2.0~15.0 | 11 | 320 |

| FS12 | T x 12 x 320 | 2.0~15.0 | 12 | 320 |

| FS13 | T x 13 x 320 | 2.0~15.0 | 13 | 320 |

| FS14 | T x 14 x 320 | 2.0~15.0 | 14 | 320 |

| FS15 | T x 15 x 320 | 2.0~15.0 | 15 | 320 |

| FS16 | T x 16 x 320 | 2.0~15.0 | 16 | 320 |

| FS17 | T x 17 x 320 | 2.0~15.0 | 17 | 320 |

| FS18 | T x 18 x 320 | 2.0~15.0 | 18 | 320 |

| FS19 | T x 19 x 320 | 2.0~15.0 | 19 | 320 |

| FS20 | T x 20 x 320 | 2.0~15.0 | 20 | 320 |

| FS22 | T x 22 x 320 | 2.0~15.0 | 22 | 320 |

| FS25 | T x 25 x 320 | 2.0~15.0 | 25 | 320 |

| FS28 | T x 28 x 320 | 2.0~15.0 | 28 | 320 |

| FS30 | T x 30 x 320 | 2.0~15.0 | 30 | 320 |

| FS32 | T x 32 x 320 | 2.0~15.0 | 32 | 320 |

| FS35 | T x 35 x 320 | 2.0~15.0 | 35 | 320 |

| FS40 | T x 40 x 320 | 2.0~15.0 | 40 | 320 |

| FS45 | T x 45 x 320 | 2.0~15.0 | 45 | 320 |

| FS50 | T x 50 x 320 | 2.0~15.0 | 50 | 320 |

| FS55 | T x 55 x 320 | 2.0~15.0 | 55 | 320 |

| Tolerance (mm) | ||

| L | >150 | -0~+L*2% |

| W | ≤8.0 | -0~+0.35 |

| 8.0~25.0 | -0~+0.50 | |

| 25.0~35.0 | -0~+0.70 | |

| >35.0 | -0~+1.20 | |

| T | ≤15.0 | -0~+0.40 |

| Flatness (mm) | ||

| W | ≤20.0 | ≤0.50 |

| >20.0 | ≤0.60 | |

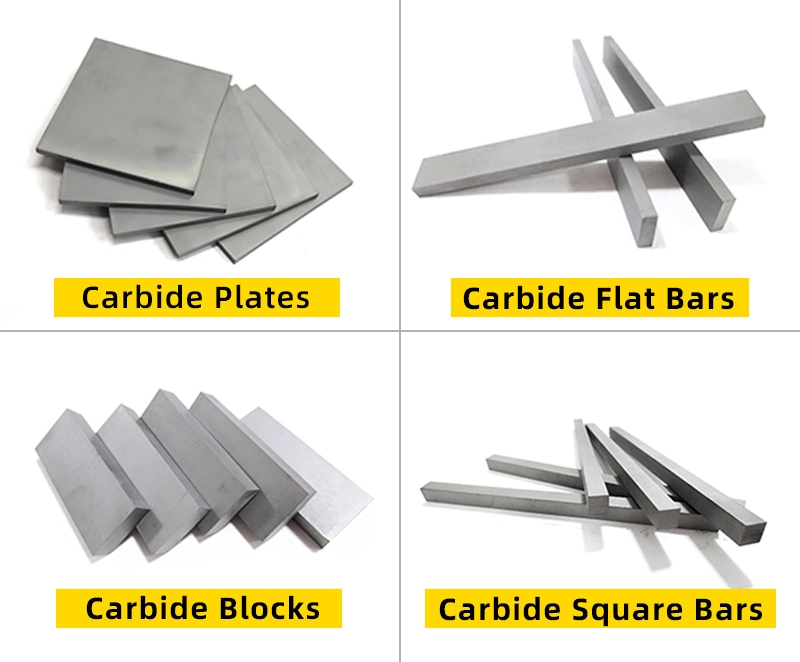

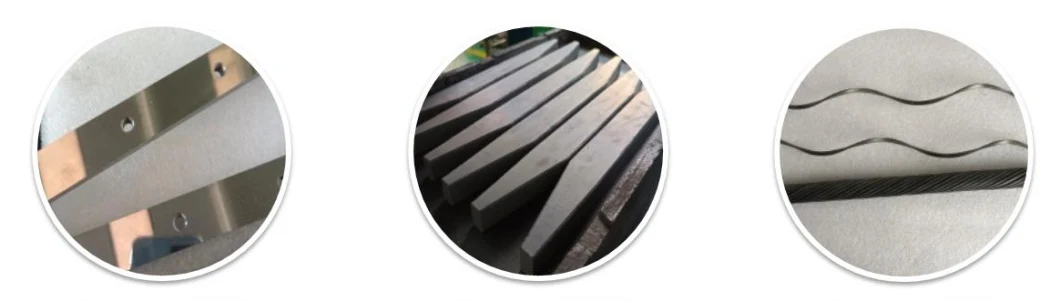

Different types of carbide strips for your selection.

carbide strips with holes carbide crushing strips carbide spiral strips

carbide strips carbide STB strips carbide plates

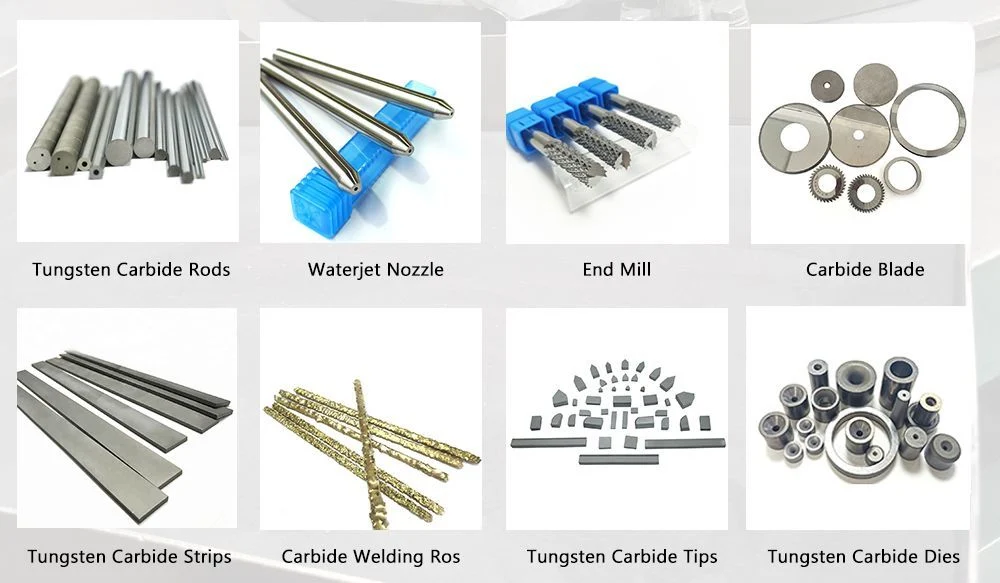

Other products you may be interest in:

1. carbide rods

2. carbide waterjet nozzle

3. carbide endmills

4. carbide round blade

5. hardfacing material like composite welding rods, carbide grit

6. carbide tips

7. carbide mould and dies

Customized product is available.

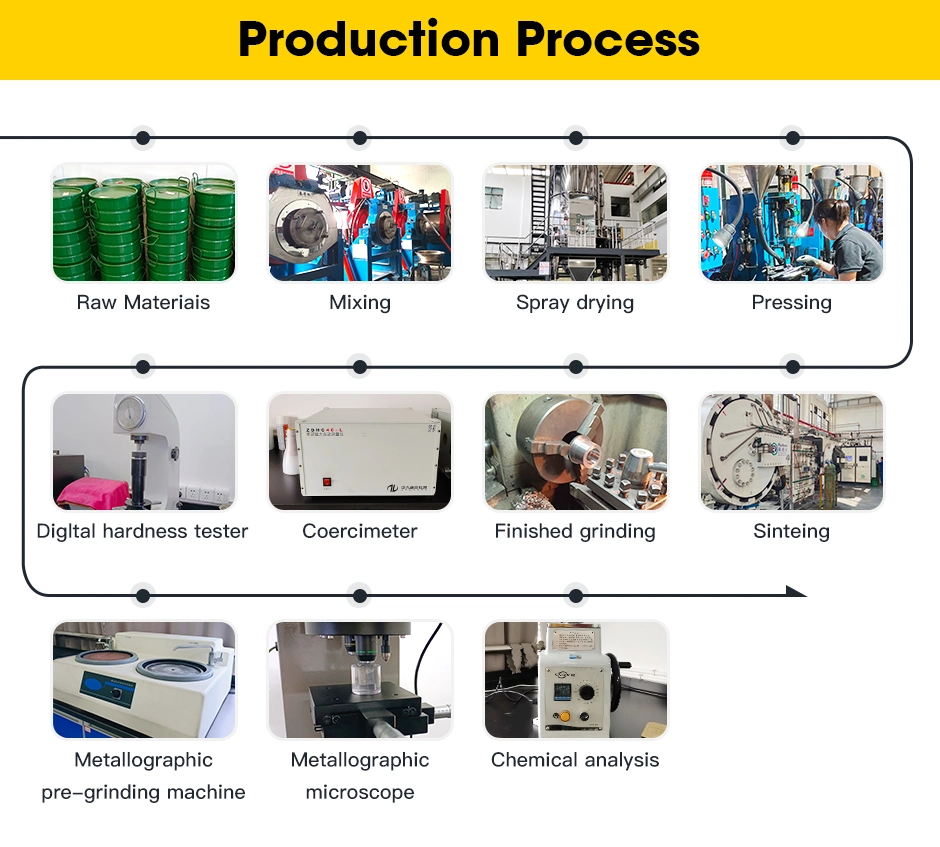

The production process for tungsten carbide:

1. powder milling and mixing

2. pressing

3. sintering

4. grinding if need

5. inspection