Basic Info.

Product Description

Introduction and Application for tungsten carbide rolls from Zhuzhou manufacturers: Tungsten carbide roller has high hardness, and their hardness values change little with temperature. Its hardness at 700°C is 4 times that of HSS.And the elastic modulus, compressive strength, bending strength, and thermal conductivity are also higher than the tool steel by more than one time.Due to the high thermal conductivity of the tungsten carbide rolls, the heat dissipation effect is good.Therefore, the cemented carbide rolls are more resistant to corrosion and cold and heat fatigue than the tool steel roll.

Tungsten carbide rollers main used to produce smooth or ribbed wire for construction reinforcement filed.

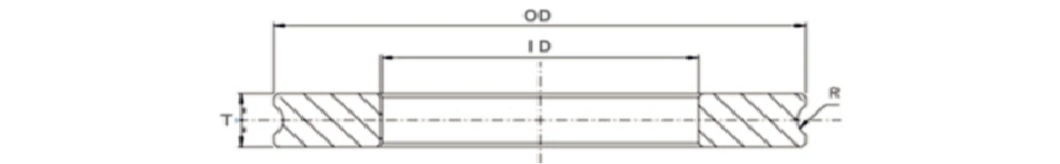

Some sizes of tungsten carbide rolls:

| Wire Range(mm) | O.D.(mm) | I.D.(mm) | Thickness(mm) |

| 4~8.5 | 123 | 82 | 15 |

| 9~12 | 123 | 82 | 20 |

| 4~8.5 | 125 | 82 | 15 |

| 9~12 | 125 | 82 | 20 |

| 4~8.5 | 140 | 90 | 15 |

| 9~12 | 140 | 90 | 20 |

| 4~8.5 | 150 | 90 | 15 |

| 9~12 | 150 | 90 | 20 |

| 4~8.5 | 160 | 90 | 15 |

| 9~12 | 160 | 90 | 20 |

| 4~8.5 | 220 | 130 | 15 |

| 9~12 | 220 | 130 | 20 |

Grade list for tungsten carbide rolls:

| ISO Grade | Co% | Density(g/cm3) | Hardness | Recommended Application |

| HRA (ISO3738) | ||||

| E10M | 10 | 14.3 | ≥86.0 | Maximum hardness,excellent wear resistance in the grade series of tungsten carbide rolls.Used in the last 1-2 stands of good high speed finishing mills for rolling common and hard steel bars. |

| E12M | 12 | 14.2 | ≥84.0 | Higher wear resistance,moderate impact resistance in the series of cemented carbide rollers.Used in the last 1-3 stands of good high speed finishing mills for rolling common and hard steel bars. |

| E15M | 15 | 14.0 | ≥83.5 | Moderate wear resistance and impact resistance,good for general purposes.Used in the last 1-4 stands or all stands of finishing mills. |

| E18M | 18 | 13.8 | ≥83.0 | Best for general purposes.Used in the front stands of good mills and in the rear stands of common mills. |

| E20M | 20 | 13.7 | ≥82.0 | Used in the first and second stands of finishing mills and in the stands of pre-finishing rolling mills.For every stand of rolling lines for low speed rolling,low precision and unstable operation. |

| E26M | 26 | 13.2 | ≥81.0 | Maximum binder content in the grade series of tungsten carbide rollers.Good toughness and thermal crack resistance.Used in the stands of the pre-finishing rolling mills and for rolling for hot rolling of ribbed steel. |

Detailed image for surface finishing:

Quality Control System: We always follow the high quality standard for production, from the material preparing to final product ready, all product will go through 3 inspections before we send them to you. Our professional teams will take care of your product and ensure the good and stable quality for all batches.

Our regular product is tungsten carbide tips, carbide inserts, end mills,carbide saw tips,carbide mining parts, carbide rods, plates and stripes.

We also have rich experience for customized product, we make your designs become real product, which perfectly match your need. We have many successful projects on the for our clients in different countries.

Packing:

A. Standard packing

1).Plastic boxes with foam inside and carton outside.

2).Paper boxes with foam inside and carton outside.

3).Inner boxes/packing material inside and plywood box outside (for heavy product).

B. Customized packing available: We can do special packing based on client's requirements..