Basic Info.

Model NO.

ZZLGJ-160102

Size

Any Size Accepted Customized

Grade

Yg6, Yg8, Yn8, Yn10

Surface

Polished or Unground

Delivery Time

15 Days

Applications

Cutting Tool

Tolerance

+/-0.05

Product Name

Cemented Carbide Strip

Quality

100% G Virgin Materials.

Shipping

DHL, FedEx, TNT, UPS, EMS

MOQ

10 Kgs

Transport Package

Carton

Specification

Customized

Trademark

Old Craftsman

Origin

Hunan

HS Code

82090090

Production Capacity

7000kg/Month

Product Description

Cemented carbide strip

1. 100% raw material to produce tungsten carbide products.

2. Hip sintered, high hardness, high wear resistance

3. Various sizes and full types available

4. Reasonable price,Fast delivery time

5. OEM Customized(small order accepted,professional technical support)

6.ISO 9001 Certification

More details of specific type, please inform us

Product information

Grade information

Company Information

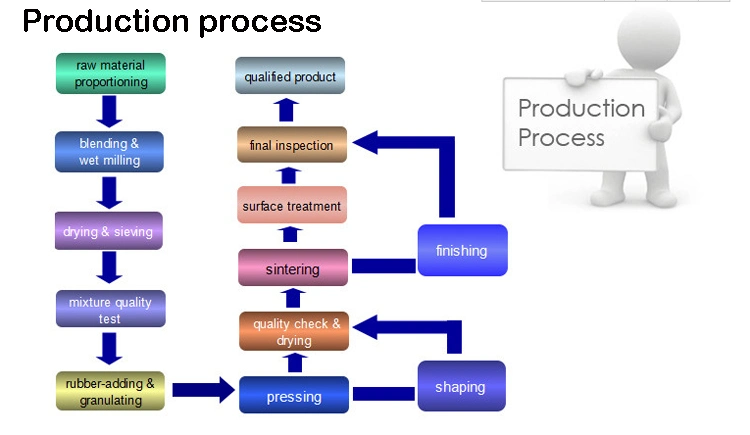

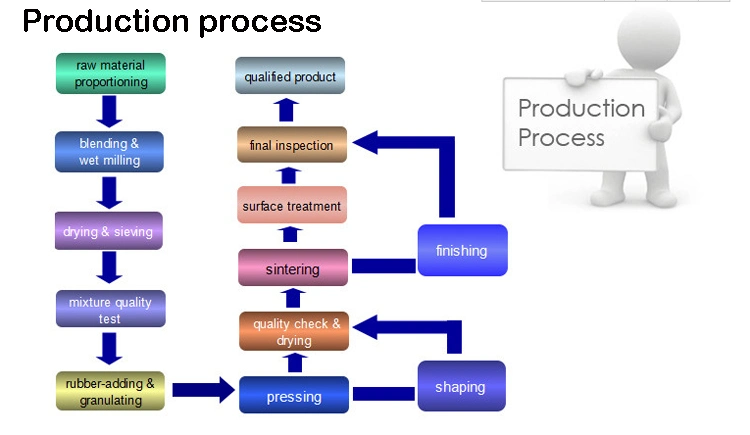

Production process

Applications

Packing and Delivery

Payment terms

RAQ

Q: Are you trading company or manufacturers?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 25-35 days if the goods are not in stock, it is according to quantity.

Q: Do you provide sample? Is it free or not?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your payment term?

A: Payment<1000USD, 100% in advance. Payment>1000USD, 30% T/T in advance, balance before shipment.

If you have other question, please feel free to contact us!

1. 100% raw material to produce tungsten carbide products.

2. Hip sintered, high hardness, high wear resistance

3. Various sizes and full types available

4. Reasonable price,Fast delivery time

5. OEM Customized(small order accepted,professional technical support)

6.ISO 9001 Certification

More details of specific type, please inform us

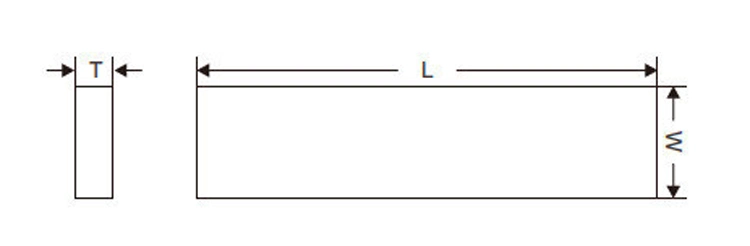

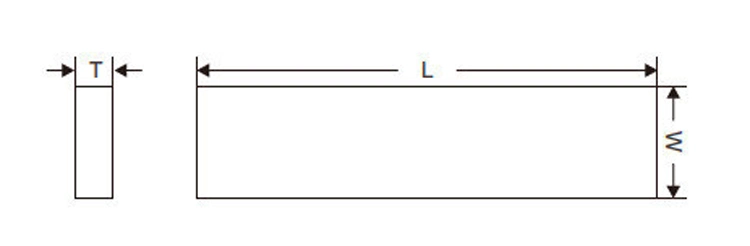

Product information

| TYPE | T (mm) | W (mm) | L (mm) | TYPE | T (mm) | W (mm) | L (mm) | |

| STB 12 | 0.8 | 1.6 | 25.4 | STB 410A | 3.2 | 7.9 | 38.1 | |

| STB 13 | 1.2 | 2.4 | 25.4 | STB 410B | 3.2 | 7.9 | 76.2 | |

| STB 13A | 1.2 | 2.4 | 20.6 | STB 412A | 3.2 | 9.5 | 50.8 | |

| STB 24A | 1.6 | 3.2 | 25.4 | STB 412B | 3.2 | 9.5 | 76.2 | |

| STB 24B | 1.6 | 3.2 | 76.2 | STB 412C | 3.2 | 9.5 | 152.4 | |

| STB 24C | 1.6 | 3.2 | 31.8 | STB 412D | 3.2 | 9.5 | 25.4 | |

| STB 26A | 1.6 | 4.8 | 25.4 | STB 416 | 3.2 | 12.7 | 152.4 | |

| STB 26C | 1.6 | 4.8 | 76.2 | STB 416A | 3.2 | 12.7 | 25.4 | |

| STB 28A | 1.6 | 6.4 | 25.4 | STB 416B | 3.2 | 12.7 | 38.1 | |

| STB 28B | 1.6 | 6.4 | 31.8 | STB 416C | 3.2 | 12.7 | 76.2 | |

| STB 28D | 1.6 | 6.4 | 76.2 | STB 420 | 3.2 | 15.9 | 152.4 | |

| STB 14 | 2.0 | 3.2 | 28.6 | STB 68 | 4.8 | 6.4 | 152.4 | |

| STB 34 | 2.4 | 3.2 | 127.0 | STB 68A | 4.8 | 6.4 | 76.2 | |

| STB 36 | 2.4 | 4.8 | 28.6 | STB 610 | 4.8 | 7.9 | 152.4 | |

| STB 36A | 2.4 | 4.8 | 31.8 | STB 610A | 4.8 | 7.9 | 76.2 | |

| STB 38A | 2.4 | 6.4 | 25.4 | STB 612 | 4.8 | 9.5 | 152.4 | |

| STB 38B | 2.4 | 6.4 | 38.1 | STB 612A | 4.8 | 9.5 | 76.2 | |

| STB 38D | 2.4 | 6.4 | 127.0 | STB 616 | 4.8 | 12.7 | 152.4 | |

| STB 310A | 2.4 | 7.9 | 50.8 | STB 616A | 4.8 | 12.7 | 76.2 | |

| STB 310B | 2.4 | 7.9 | 76.2 | STB 620 | 4.8 | 15.9 | 152.4 | |

| STB 310C | 2.4 | 7.9 | 127.0 | STB 620A | 4.8 | 15.9 | 76.2 | |

| STB 312 | 2.4 | 9.5 | 127.0 | STB 812 | 6.4 | 9.5 | 152.4 | |

| STB 46 | 3.2 | 4.8 | 152.4 | STB 812A | 6.4 | 9.5 | 76.2 | |

| STB 48A | 3.2 | 6.4 | 25.4 | STB 816 | 6.4 | 12.7 | 152.4 | |

| STB 48B | 3.2 | 6.4 | 31.8 | STB 816A | 6.4 | 12.7 | 76.2 | |

| STB 48C | 3.2 | 6.4 | 57.2 | STB 820 | 6.4 | 15.9 | 152.4 | |

| STB 48D | 3.2 | 6.4 | 76.2 | STB 820A | 6.4 | 15.9 | 76.2 | |

| STB 48E | 3.2 | 6.4 | 152.4 | STB 824 | 6.4 | 19.1 | 152.4 | |

| STB 410 | 3.2 | 6.4 | 152.4 | STB 824A | 6.4 | 19.1 | 76.2 |

| Tungsten carbide grade introduction | |||||

| Grade | Equivalent | Hardness | Bending strength | Density | Performances & Applications |

| to ISO | (HRA)≥ | (N/mm2)≥ | (g/cm3)≥ | ||

| YG6X | K10 | 91.3 | 1580 | 14.8-15.1 | |

| YG6A | K05-K10 | 14.9 | 1860 | 92 | |

| YG6 | K20 | 89.8 | 1700 | 14.7-15.1 | |

| YN8 | K30/K20 | 90.5 | 1880 | 14.5-14.9 | |

| YG8 | K30 | 89.5 | 1890 | 14.6-14.9 | |

| YG8C | K30 | 88.3 | 2100 | 14.5-14.9 | |

| YG15 | - | 87.3 | 2250 | 13.9-14.2 | |

| YG10X | K35 | 89.5 | 2200 | 14.3-14.7 | |

| YS2T | M30/K30 | 91.8 | 3600 | 14.3-14.6 | |

| YL10.2 | - | 91.2 - 91.8 | 3600 | 14.4-14.6 | Co:10 TA(NI)C: 1-1.5%Grain Size: 0.6-0.8 umThe rest: WC |

| YG11C | K40 | 86.8 | 2300 | 14.1-14.5 | |

Company Information

Production process

Applications

Tungsten carbide strips are widely used in production of processed wood, MDF, cast iron, on-ferrous materials, chilled cast iron, hardened steel, PCB, brake materials etc.

Packing and Delivery

Payment terms

RAQ

Q: Are you trading company or manufacturers?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 25-35 days if the goods are not in stock, it is according to quantity.

Q: Do you provide sample? Is it free or not?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your payment term?

A: Payment<1000USD, 100% in advance. Payment>1000USD, 30% T/T in advance, balance before shipment.

If you have other question, please feel free to contact us!