- Overview

- Quick Information

- Our Advantages

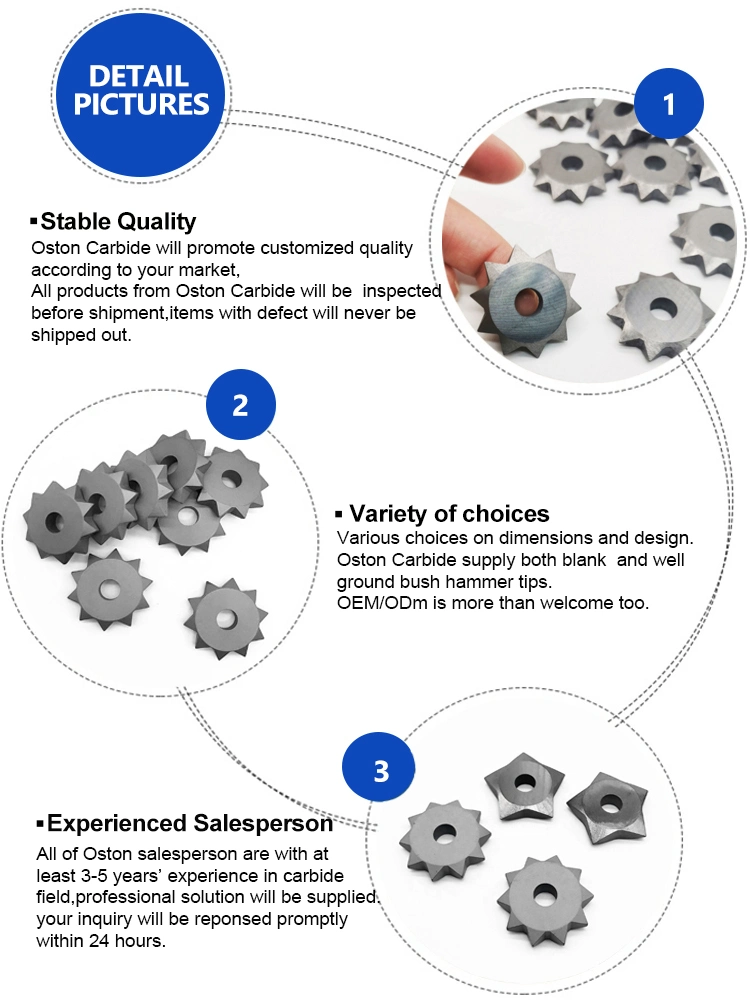

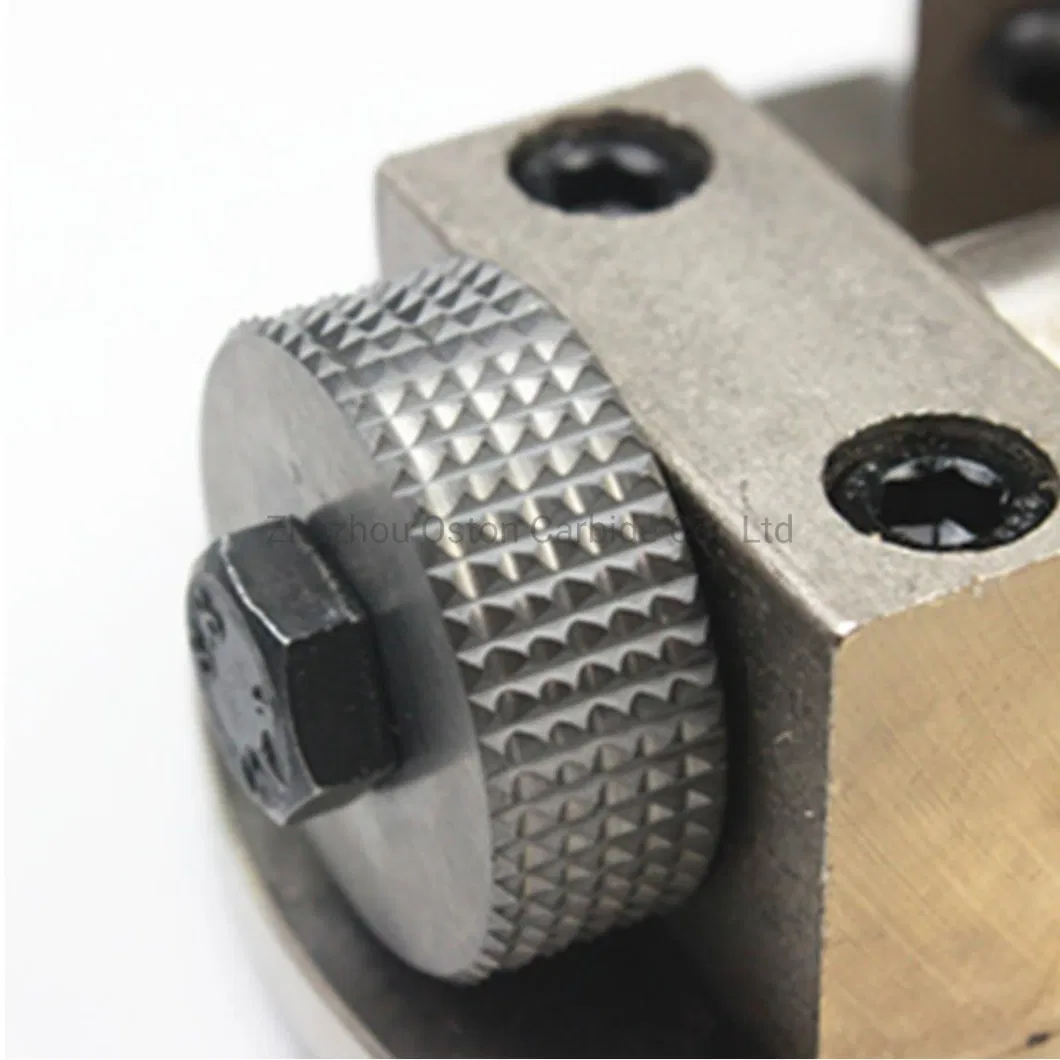

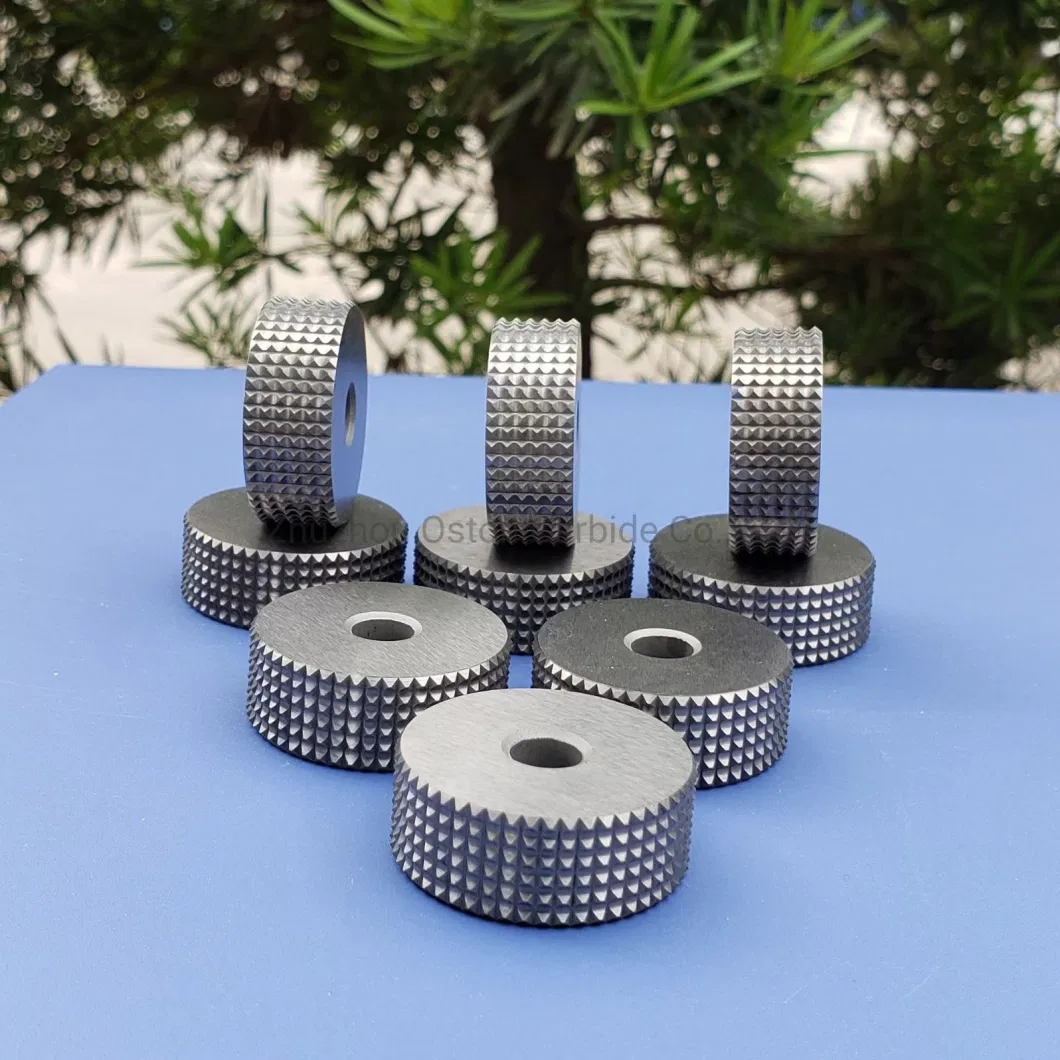

- Detailed Photos

- Quality Grade

- Quality Control

- About Oston Carbide

Basic Info.

Packaging & Delivery

Product Description

Bush Hammer Roller is designed to pulverize the surface of concrete making it fast and easy to get to full aggregate exposure. This technique is also recommended for every smooth surface you want to make anti-skid ,and it is also widely used for coating removal.

Product Name | Tungsten Carbide Milling Wheels for Knurling Bush Hammer Roller Plates |

Material | Tungsten carbide 100% original material |

Quality Grade | YG8, YG8C,YG11C,YG13C |

| Surface treatment | Blank one, well ground ones,etc |

Specifications | Existed dimension:Φ33×Φ8.0×6.5mm-10 tooth, Φ33×Φ8.0×6.5mm-5 tooth,Φ49.2xΦ20x6.0mm-15 tooth,Φ33xΦ13.0*6.0mm-10 tooth,Φ33xΦ8*12mm-312tooth, we also can customize the carbide tips for bush hammer as per your samples or drawings. |

Application | Concrete Surface Dressing Bush Hammer Tool Parts |

Free Sample | 1-2 pcs available if we have stock |

MOQ | 50 PCS |

Delivery Time | 20-22 days for one batch |

Delivery Port | Guangzhou,Shenzhen,Shanghai,Ningbo |

Payment Terms | 30% T/T deposit, balance before shippment |

Grades | Density(g/cm³) | Hardness(HRA) | T·R·S(N/mm2) | Application |

YG6 | 14.80 | 89.5 | 1700 | Mainly used as the buttons of small and medium-sized percussion bits and as the inserts of rotary prospecting bits to cut soft, medium-hard formations. |

YG8 | 14.70 | 88.5 | 2300 | Mainly used as the buttons of small and medium-sized percussion bits and as the inserts of rotary prospecting bits to cut soft, medium-hard formations. |

YG8C | 14.70 | 88.0 | 2300 | Mainly used as the buttons of small and medium-sized percussion bits and as the inserts of rotary prospecting bits to cut soft, medium-hard formations. |

| 14.50 | 87.0 | 2400 | Mainly used as the inserts and buttons for rotary-percussive bits, coal-cutting bits and tricone bits to cut medium-hard and hard formations. |

YG11C | 14.40 | 86.5 | 2450 | Chiefly for the inserts and buttons of heavy rock drill bits and rotary-percussive bits, coal-cutting bits and tricone bits to cut medium-hard and hard formations. |

YG13C | 14.30 | 86.0 | 2500 | Mainly used as the inserts and buttons of tricone bits rotary-percussive bits and heavy rock drill bits to cut medium-hard and hard formations. |

YG15 | 14.00 | 86.5 | 2500 | It is stronger, and is mainly used as the inserts and buttons of rotary-percussive bits, heavy rock drill bits to cut hard and very hard formations. |

YG16 | 14.10-14.30 | 87.5 | 2400 | It is mainly used for making cemented carbide substrate tips to be used in PDC cutters for excavating coal and oil field PDC bits. |

YG20 | 13.40-13.70 | 85.0 | 2254 | Mainly for the stamping dies used in the conditions of heavy impact load and large strees. |

1. Material Milling and Desiccation

Dust-Free Workshop: All staff must wear specified uniforms before entering the workshop.

2. TPA suppressing and HIP sintering

Machinery Automation:Automatic manipulators are installed for all of our TPA suppressing facilites,which is more accurate on weight controlling and reduces production cost.

Strict rules of operation: All operation need be conducted strictly as process rules.

3. Quality checking of trial production.

New testing piece: Testing piece must be produced before a new batch of material is used for mass production to ensure the stable quality.

4.Grinding and Machining

We own all facilitess for the whole carbide machining system to ensure the delivery in time,including surface grinding lathe,external grinding lathe,centerless grinding lathe,wire cutting machine,EDM sparkling machine.

5.quality checking of finished products and package.

Double Quality Checking: Inspection for semi-finished and finished products are both essential,products with defects will never be shipped.

Safe package and delivery: Kraft paper for the first layer,bubble plastic for the second layer,gaps are filled with sponge,We focus on every package detail to ensure that clients receive our goods with good looks and good quality.

Q:What kind of products and service could OSTON supply ?

A:OSTON has been specializing in carbide solutions more than 20 countries,which includes design and manufacturing of various carbide parts.

Q: Is there any certification for products of OSTON ?

A: Yes,All products from OSTON have been endorsed with the ISO9001:2015 certification.

Q:Can a drawing be supplied to OSTON for further design ?

A: Yes,we encourage sending as more information as possible,drawing and sketch are welcome for specific quotation,even a sample could be sent to OSTON for further design.

Q:When can I get the offer after sending inquiry ?

A:Our sales operates between 9:00 am to 6:00 pm Monday to Friday,Offer is usually supplied within 24 hours after we got your inquiry,if you are urgent to get the price,please call us or send email so that we'll take it as priority.

Q:How long time I need spend on waiting for my goods ?

A:Usual delivery time is 15-18 days after 30% down payment is received,please confirm with us before placing the order if you need urgent turnaround delivery.