- Overview

- Product Description

- Product Parameters

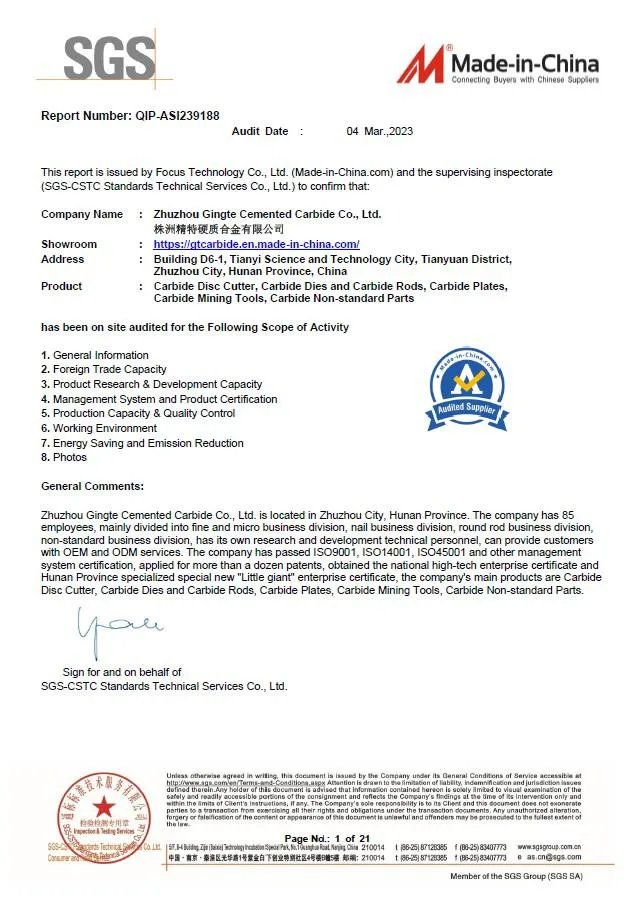

- Company Profile

- Packaging & Shipping

- Certifications

Basic Info.

Transport Package

Paper Box

Specification

OEM

Trademark

NO

Origin

Zhuzhou, Hunan, China

Production Capacity

240t/Year

Product Description

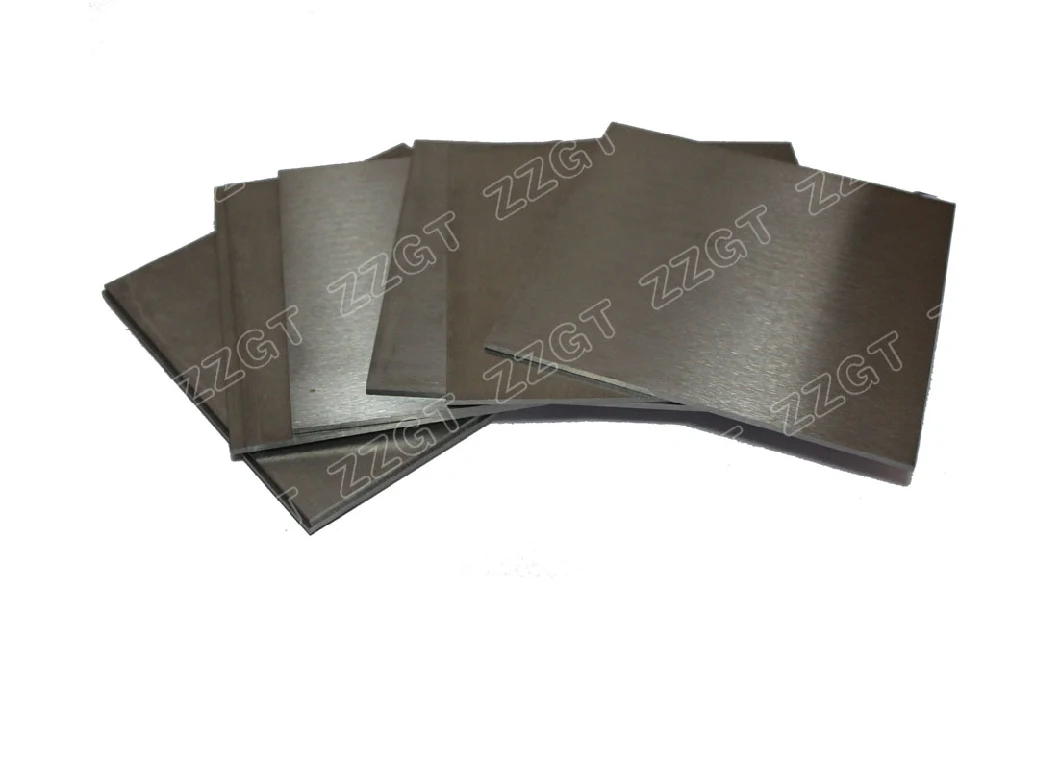

Wear Resistance Tungsten Carbide wear tool Parts Carbide Plate

HIP sintering tungsten carbide plates have excellent red toughness,high hardness,good wear resistance,high elasticmodulus,high strength,good chemical stability,acid,alkali,high temperatureoxidation,Low impact toughness,low expansion coefficient,thermal conductivity,the characteristics of the conductive similar to iron and other alloy.

1. having all kind sizes for your choose,can supply less than 400mm length.

2. Sintere by vacuum sintering furnace and HIP machine with excellent specifications without any hole.

3. suply blank plate with tolerance(-0.15~+0.15)or (0~+0.3).

4. can grinding and polishing the side and blading.

5. delivery time is 10-12 days.

| Tungsten Carbide Plates | |||||

| Grades | Density | T.R.S | Hardness | Performance & application recommended | |

| g/cm³ | MPa | HRA | |||

| YG11 | 14.4 | ≥3000 | 88.5 | Forming or stamping dies for metal powders and nonmetal powders. | |

| YG15 | 14 | ≥3400 | 87.5 | For fabricating drawing dies of steel tubes and rods under High compressibility ratio; punching, stamping, forging tools under large stress. | |

| YG20 | 13.5 | ≥3800 | 85.5 | For fabricating of stamping dies for watch parts, spring plates of musical instruments, battery jars, small sized steel balls, screws, screw caps. | |

| YG15C | 14 | ≥4000 | 86.5 | For oil cone drill bits,cut medium soft and hard rocks;debarking and cutting of frozen wood,soft wood and original wood. | |

| YG16C | 13.9 | ≥3500 | 85.5 | Impact resistance forging dies. | |

| YG18C | 13.7 | ≥3600 | 84.5 | Impact resistance forging dies, hot-press forging dies and rollers. | |

| YG20C | 13.5 | ≥3800 | 83.5 | Dies for wear resistant or impact resistant application. | |

| YG22C | 13.3 | ≥4000 | 83 | Nut forming dies and high impact resistance forging dies. | |

| GT55 | 13.1 | ≥4250 | 82.5 | Stainless bolt header dies and rollers. | |