Basic Info.

Product Description

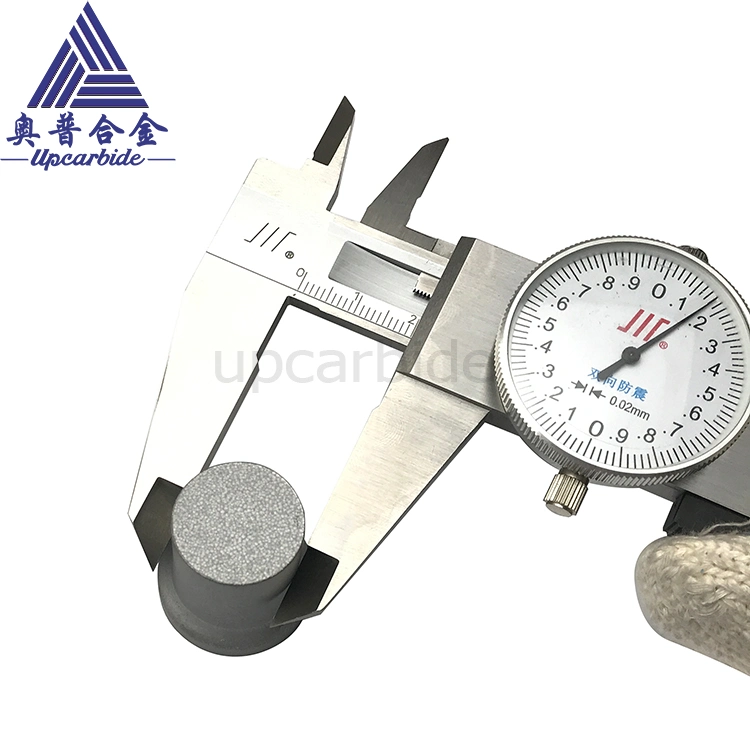

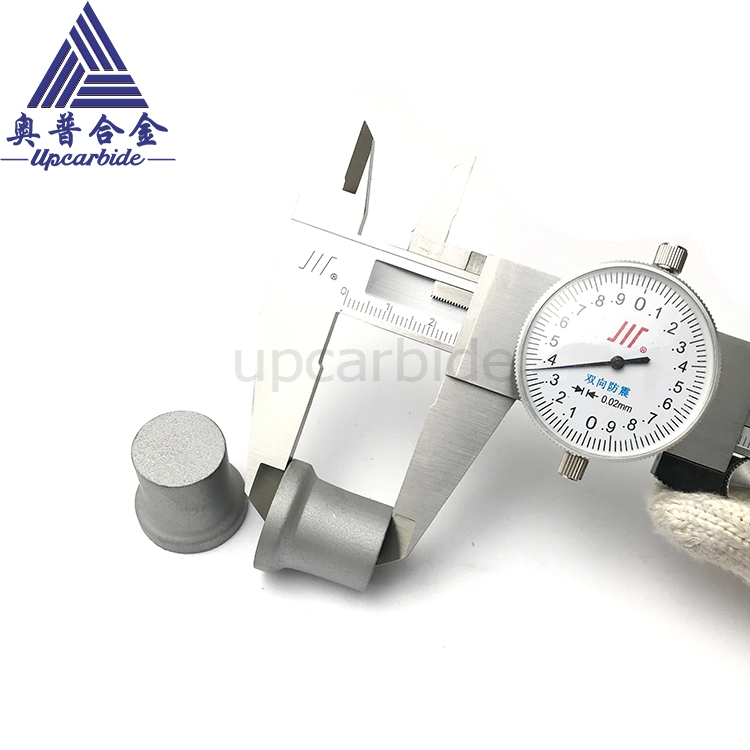

tungsten carbide button has superior wear resistance and impact toughness, and similar

products with higher speed of drilling and digging.Series of ball tooth bit passivation

using cycle is long, not to grind the life span of about the same diameter RenPian grinding

head drill bit 5-6 times of life, is beneficial to save auxiliary working hours, physical labor

and reduce workers to speed up the project.

1. promise the 100% virgin material .

2. Sintere by vacuum sintering furnace and HIP machine with excellent specifications without any hole.

3. suply blank and surface passivation.

4. tungsten carbide button's high hardness of the cemented carbide and other characteristics are widely used in mining and quarrying and cutting process, also may be placed on a heavy excavators used in bit.

5. we can product the goods according your drawing and sizes.

6. our new product grade's grain size can up to 6.0μm,highest wear-resisting and excellentest impact resistance.

Grade

| Density (g/cm3) | T.R.S ( MPa) | Hardness (HRA) | Application recommended |

YG6 | 14.95 | ≥1900 | ≥90.5 | For coring crowns,electric coal drill bits,coal cutting picks,oil cone bits and scraping knife bits,used in geological prospecting,coal mining and oil well boring. |

YG8 | 14.80 | ≥2200 | ≥89.5 | Used as a core drill, electric coal drill, coal cutter tooth, oil roller bit and scraper button bit. |

YG8C | 14.80 | ≥2400 | ≥88.5 | Mainly used for small and medium-sized drill bit tooth, and as a rotating exploration drill bush. |

YG11C | 14.40 | ≥2700 | ≥86.5 | Most used in the drill bit and rock bit used for cutting high hardness materials ball tooth. |

YG13C | 14.2 | ≥2850 | ≥86.5 | mainly used for rotary drill bit used for cutting high hardness materials in ball mill. |

YG15C | 14.0 | ≥3000 | ≥85.5 | Used in oil cone bit and soft in the hard rock digging cutting tools. |

YK05 | 14.8 | ≥2500 | ≥90.5 | Mostly used as the buttons of small and mediumsized bits to cut soft and medium hard formations |

YK15 | 14.6 | ≥2450 | ≥87.6 | Suitable to strips,conical buttons for rotary percussion-resistant geological prospecting buttons,cut soft and medium hard formations. |

YK20 | 14.4 | ≥2500 | ≥86.8 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and very hard formations, |

YK25 | 14.4 | ≥2550 | ≥87.2 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard,hard,and very hard formations. |