Basic Info.

Model NO.

2DT-6LD0550-H

Shank Diameter

6

Angle

140 Degree

Controlling Mode

CNC Machine

Machine Type

Milling Machine

Transport Package

Box

Specification

D5.5*44*D6*82

Trademark

YINLK

Origin

China

Product Description

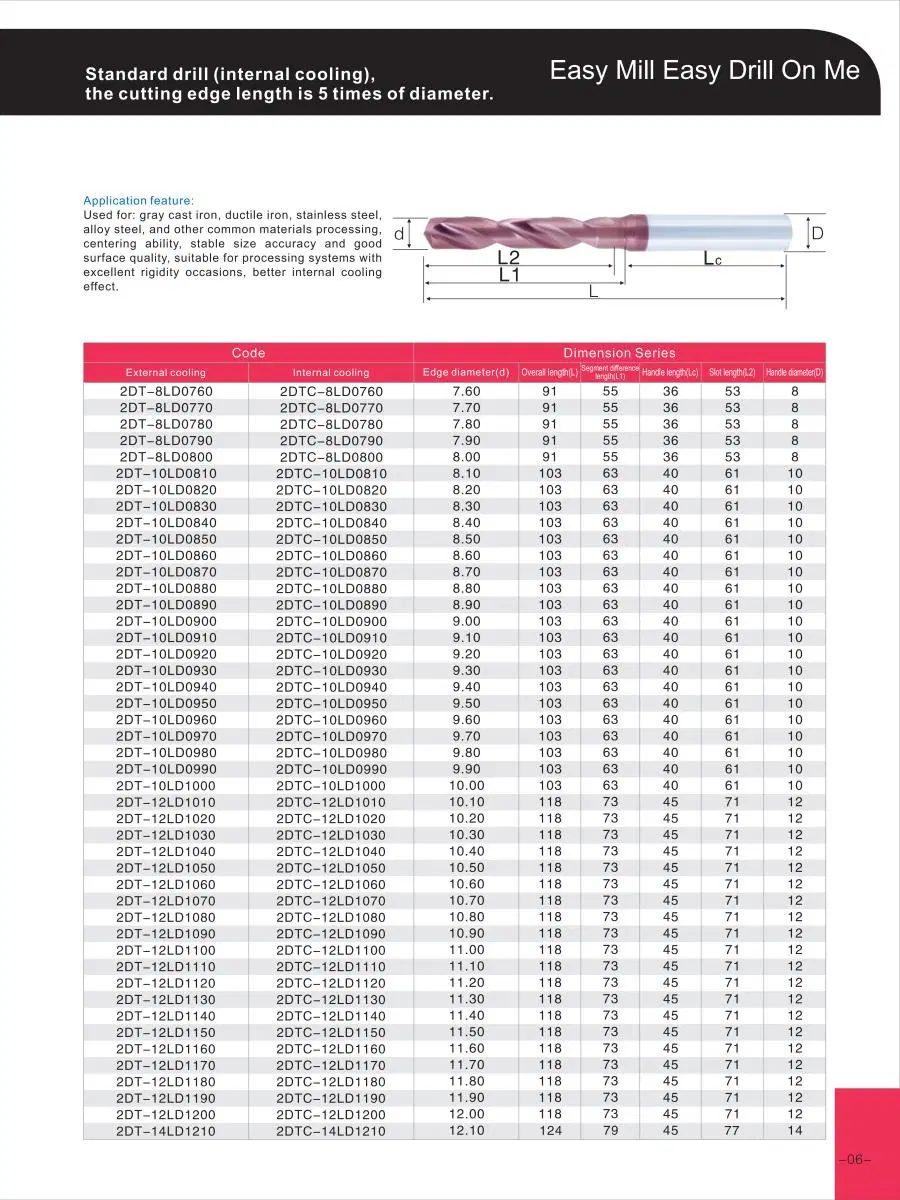

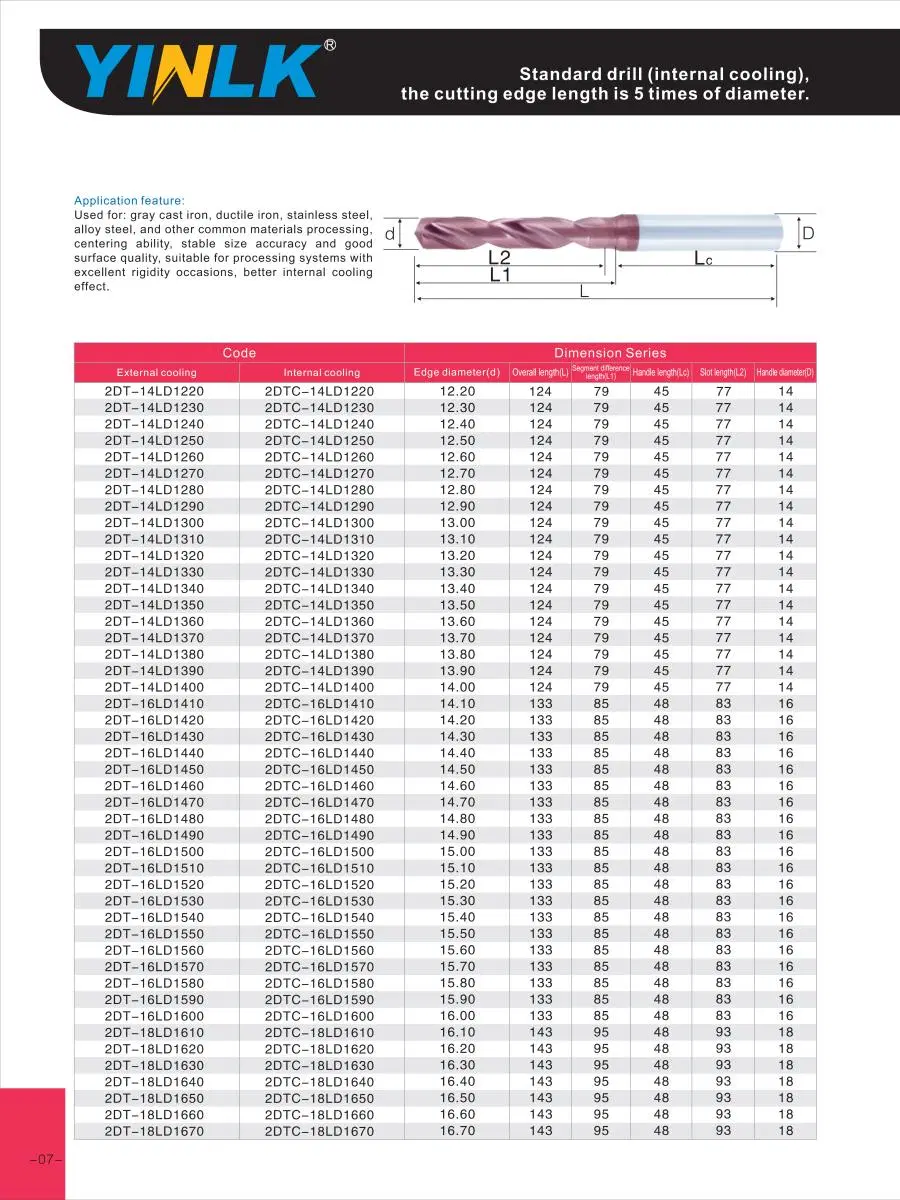

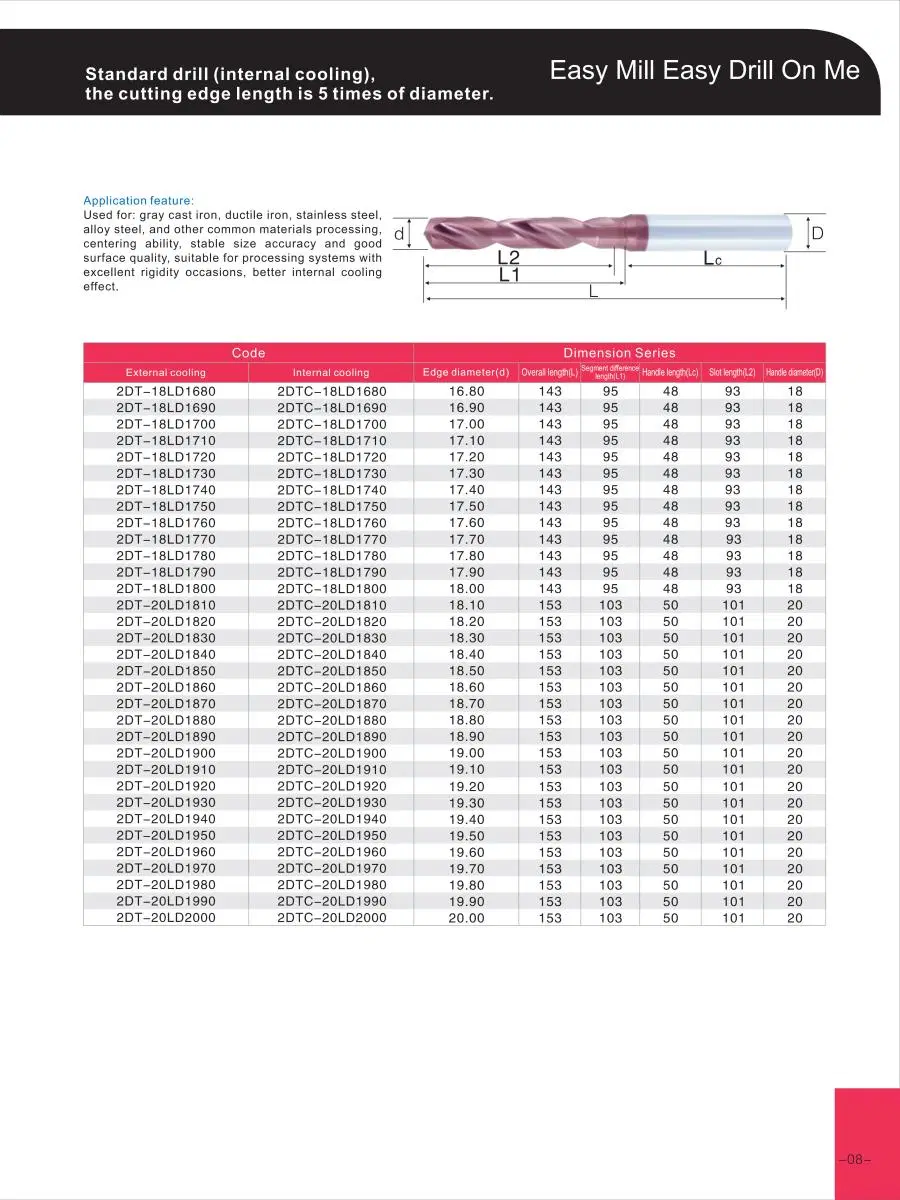

Application feature:

Used for: gray cast iron, ductile iron, stainless steel,

alloy steel, and other common materials processing,

centering ability, stable size accuracy and good surface quality,

suitable for processing systems with excellent rigidity occasions,

better internal cooling effect.

Used for: gray cast iron, ductile iron, stainless steel,

alloy steel, and other common materials processing,

centering ability, stable size accuracy and good surface quality,

suitable for processing systems with excellent rigidity occasions,

better internal cooling effect.

Company Profile

Taizhou Yinlk Tools Co., Ltd., established in the spring of 2010, is located in the

beautiful and rich Zhejiang Wenling on the coast of the East China Sea. It is a

company with a world-class German Walter 5-axis linkage tool grinding

machine and HELICHECK PLUS precision testing equipment.

The company specializes in the development and manufacture of hard alloy end mills,

The company specializes in the development and manufacture of hard alloy end mills,

drill bits, reamers, boring tools, etc. Non-standard rotary precision cutting tools.

Provide complete solutions for mold manufacturing, automotive parts processing,

advanced cutting and hole machining technology for the aerospace industry.

advanced cutting and hole machining technology for the aerospace industry.

The market is ever-changing. Since the beginning of 2012,

we have focused on the research of solid carbide drills.

In 2014, we developed special milling cutters and stainless steel cutters.

With the continuous expansion of production scale,

the for mation of product standardization, high efficiency market demand.

High-feed U-groove drills and U-grooves with different helical pitch cutters

have also been introduced to the market.

we have focused on the research of solid carbide drills.

In 2014, we developed special milling cutters and stainless steel cutters.

With the continuous expansion of production scale,

the for mation of product standardization, high efficiency market demand.

High-feed U-groove drills and U-grooves with different helical pitch cutters

have also been introduced to the market.

Packaging & Shipping

Exhibition